| Fig. 1: Exploded view of front hub components with

drum brakes

|

| Fig. 2: Exploded view of front hub components with

disc brakes, through 1984

|

| Fig. 3: Exploded view of 1986 front hub components

|

| Fig. 4: To repack the front wheel bearings, pry off

the dust cap . . .

|

| Fig. 5: . . . remove the cotter pin . . .

|

| Fig. 6: . . . and the nut lock . . .

|

| Fig. 7: . . . then loosen and remove the adjusting

nut and flat washer . . .

|

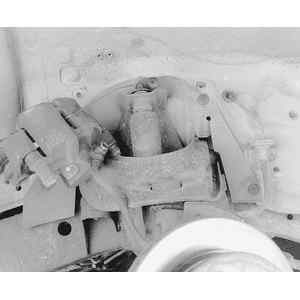

| Fig. 8: . . . next, loosen and remove the caliper bracket-to-steering

knuckle bolts . . .

|

| Fig. 9: . . . pull off the complete caliper/bracket

assembly . . .

|

| Fig. 10: . . . and suspend out of the way with a piece

of wire or rope

|

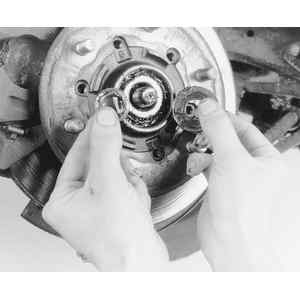

| Fig. 11: Now grab hold of the rotor and carefully pull

it — be sure to catch the outer wheel bearing as you

pull the rotor off

|

| Fig. 12: Pry off the rear grease seal to get to the

inner wheel bearing

|

| Fig. 13: With the seal removed, the inner bearing may

be withdrawn from the hub

|

| Fig. 14: Thoroughly pack the bearing with fresh, high

temperature wheel-bearing grease before installation

|

| Fig. 15: Apply a thin coat of fresh grease to the new

inner bearing seal lip

|

| Fig. 16: Use a suitably sized driver to install the

inner bearing seal to the hub

|

| Fig. 17: Driving out the bearing races

|

| Fig. 18: Thoroughly pack the bearings with grease

|

| Fig. 19: Pressing the seal into place — a

block of wood and a hammer can also be used

|

NOTE: Sodium-based grease is not compatible with lithium-based

grease. Read the package labels and be careful not to mix the two types. If

there is any doubt as to the type of grease used, completely clean the old

grease from the bearing and hub before replacing.

Before handling the bearings, there are a few things that you should remember

to do and not to do. Remember to DO the following:

Remove all outside dirt from the housing before exposing the bearing.

Treat a used bearing as gently as you would a new one.

Work with clean tools in clean surroundings.

Use clean, dry canvas gloves, or at least clean, dry hands.

Clean solvents and flushing fluids are a must.

Use clean paper when laying out the bearings to dry.

Protect disassembled bearings from rust and dirt. Cover them up.

Use clean rags to wipe bearings.

Keep the bearings in oil-proof paper when they are to be stored or are not

in use.

Clean the inside of the housing before replacing the bearing.

Do NOT do the following:

Don't work in dirty surroundings.

Don't use dirty, chipped or damaged tools.

Try not to work on wooden work benches or use wooden mallets.

Don't handle bearings with dirty or moist hands.

Do not use gasoline for cleaning; use a safe solvent.

Do not spin-dry bearings with compressed air. They will be damaged.

Do not spin dirty bearings.

Avoid using cotton waste or dirty cloths to wipe bearings.

Try not to scratch or nick bearing surfaces.

Do not allow the bearing to come in contact with dirt or rust at any time.

- Raise and support the front end on jackstands.

- Remove the wheel.

- Remove the grease cap, cotter pin, hub nut and flat washer.

- On trucks with disc brakes, remove the caliper and suspend it out of the

way without disconnecting the brake line. Slowly pull the hub from the spindle,

positioning your hand to catch the outer bearing.

- Remove the spacer, inner seal and inner bearing. Discard the seal.

- Thoroughly clean the bearings and inside of the hub with a nonflammable

solvent. Allow them to air dry.

- Inspect the bearings for wear, damage, heat discoloration or other signs

of fatigue. If they are at all suspect, replace them. When replacing bearings,

it is a good idea to replace the bearing races as a set, as bearings do

wear the races in a definite pattern which may not be compatible with new

bearings.

- To replace the races, carefully drive them out of the hub with a drift.

- Coat the outside of the new races with clean wheel bearing grease and

drive them into place until they bottom in their bore. Make certain that

they are completely bottomed! A drift can be used as a driver, if you hammer

evenly around the rim of the race and are very careful not to slip and scratch

the surface of the race. A driver made for the purpose is much easier to

use.

- Pack the inside of the hub with clean wheel bearing grease until it is

flush packed.

- Pack each bearing with clean grease, making sure that it is thoroughly

packed. Special devices are sold for packing bearings. They are inexpensive

and readily available. If you don't have one, just make certain that the

bearing is as full of grease as possible by working it in with your fingers.

- Install the inner bearing and seal. Drive the seal into place carefully

until it is seated.

- Install the spacer and the hub on the spindle.

- Install the outer bearing, flat washer and hub nut.

- Adjust the bearing as explained above.

- Install the nut cap, cotter pin and grease cap. Install the wheel.