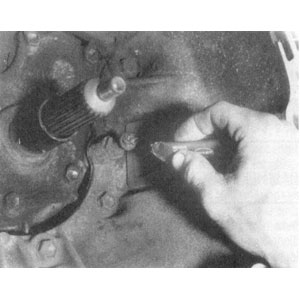

| Fig. 1: Grease the clutch release fork ball

|

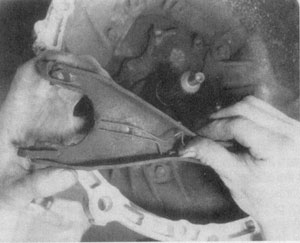

| Fig. 2: View of the clutch release fork; check this

for signs of damage

|

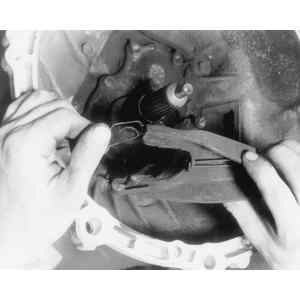

| Fig. 3: View of the clutch release fork bearing clips;

make sure these are not bent or broken

|

| Fig. 4: Removing the clutch release fork bearing clips

|

| Fig. 5: Grease the throwout bearing assembly at the

outer contact points

|

| Fig. 6: Grease the throwout bearing assembly at the

inner contact points

|

| Fig. 7: Installing the clutch release fork bearing

clip

|

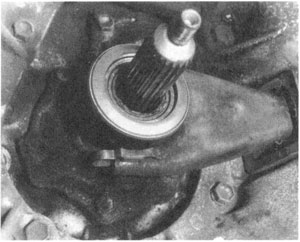

| Fig. 8: View of the clutch release fork assembly installed;

be sure all parts move freely

|

CAUTION

The clutch driven disc may contain asbestos, which has been determined to

be a cancer causing agent. Never clean clutch surfaces with compressed air!

Avoid inhaling any dust from any clutch surface! When cleaning clutch surfaces,

use a commercially available brake cleaning fluid.

NOTE: The transmission must be removed to perform the following

steps.

- Most earlier models have a spring attached to the release bearing (throwout

bearing) collar. If present, remove this spring. The release lever (fork)

is retained by either a spring (earlier models) or a spring clip (1976 and

later). Remove the spring and pull the fork from the pivot pin.

- Remove the lever, dust cover boot and the release (throwout) bearing.

- Inspect the parts carefully. Wipe off all the oil and dirt from the bearing,

but do not soak it in solvent; it is prelubricated. Any burrs should be

smoothed with crocus cloth. If burrs are present, inspect the transmission

input shaft bearing retainer, and smooth any scoring with crocus cloth.

- Coat the bearing retainer with a thin film of lithium base grease. Apply

a thin film of this grease to both sides of the fork at contact points.

Also lightly coat the release bearing surface where it contacts the pressure

plate fingers.

- Fill the grease groove inside the bearing hub with the lithium grease.

Do not use polyethylene grease. Clean any excess grease from the bore of

the hub, because excess grease will eventually work its way into the clutch

disc.

- Before installing the bearing, hold the inner race and rotate the outer

race, applying pressure. If the rotation is noisy or rough, replace the

bearing. Bearing failure is generally caused by improper free-play settings

at the release cylinder or pedal. Riding the pedal can reduce clearance,

causing the bearing to constantly spin, increasing wear. The bearing can

also fail due to release lever misalignment (bent out of plane or not centered

on the housing bracket) or misalignment between the engine and transmission.

- Apply a thin film of lithium grease to the input shaft bearing retainer

portion of the clutch housing.

- Dab the end of the pivot pin with grease, and drive the release lever

onto it. Apply a thin film of grease to the contact points of the release

lever, and install the release bearing. Hook the release collar spring back

into place (if applicable).

- Check the operation of the release bearing hub. It should slide freely

on the input shaft bearing retainer.

- Install the dust boot.