A normal set of spark plugs usually requires replacement after about 20,000–30,000

miles (32,000–48,000 km), depending on your style of driving. In normal

operation plug gap increases about 0.001 in. (0.025mm) for every 2500 miles

(4000 km). As the gap increases, the plug's voltage requirement also increases.

It requires a greater voltage to jump the wider gap and about two to three times

as much voltage to fire the plug at high speeds than at idle. The improved air/fuel

ratio control of modern fuel injection combined with the higher voltage output

of modern ignition systems will often allow an engine to run significantly longer

on a set of standard spark plugs, but keep in mind that efficiency will drop

as the gap widens (along with fuel economy and power).

NOTE: Platinum tipped spark plugs usually require replacement

after about 50,000–60,000 miles (80,000–96,000 km). However, some

manufacturers have recommended replacement at 100,000 miles (160,000 km).

When you're removing spark plugs, work on one at a time. Don't start by removing

the plug wires all at once, because, unless you number them, they may become

mixed up. Take a minute before you begin and number the wires with tape.

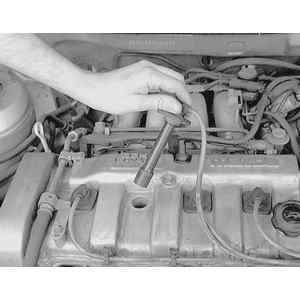

| Fig. 1: To remove a spark plug, first remove the plug

wire attached to the plug. Only detach one wire at a time

|

- Disconnect the negative battery cable, and if the vehicle has been run recently,

allow the engine to thoroughly cool.

- On all engines except the 2.3L V6, carefully twist the spark plug wire boot

to loosen it, then pull upward and remove the boot from the plug. Be sure

to pull on the boot and not on the wire, otherwise the connector located inside

the boot may become separated.

- On 2.3L V6 engines, remove the ignition coil as follows:

- For the front bank of spark plugs, remove the charge air cooler.

- For the rear bank of spark plugs, remove the solenoid bracket assembly.

- Detach the ignition coil 4-pin connector.

- Remove the ignition coil attaching screws and remove the coil by pulling

it straight up.

- Using compressed air, blow any water or debris from the spark plug well

to assure that no harmful contaminants are allowed to enter the combustion

chamber when the spark plug is removed. If compressed air is not available,

use a rag or a brush to clean the area.

NOTE: Remove the spark plugs when the engine is cold, if

possible, to prevent damage to the threads. If removal of the plugs is difficult,

apply a few drops of penetrating oil or silicone spray to the area around

the base of the plug, and allow it a few minutes to work.

| Fig. 2: Then, using a spark plug socket with a rubber

insert, loosen the plug by turning it counterclockwise

|

- Using a spark plug socket that is equipped with a rubber insert to properly

hold the plug, turn the spark plug counterclockwise to loosen and remove the

spark plug from the bore.

WARNING

Be sure not to use a flexible extension on the socket. Use of a flexible

extension may allow a shear force to be applied to the plug. A shear force

could break the plug off in the cylinder head, leading to costly and frustrating

repairs.

| Fig. 3: Finally, remove the socket, with plug retained

by the insert, and inspect the spark plug

|

To install:

- On all engines except the 2.3L V6, inspect the spark plug boot for tears

or damage. If a damaged boot is found, the spark plug wire must be replaced.

- On 2.3L V6 engines, inspect the coil-to-spark plug connection area for cracks

or damage. If damage to the coil is found, replace the assembly.

- Using a wire feeler gauge, check and adjust the spark plug gap. When using

a gauge, the proper size should pass between the electrodes with a slight

drag. The next larger size should not be able to pass while the next smaller

size should pass freely.

- Carefully thread the plug into the bore by hand. If resistance is felt before

the plug is almost completely threaded, back the plug out and begin threading

again. In small, hard to reach areas, an old spark plug wire and boot could

be used as a threading tool. The boot will hold the plug while you twist the

end of the wire and the wire is supple enough to twist before it would allow

the plug to crossthread.

WARNING

Do not use the spark plug socket to thread the plugs. Always carefully thread

the plug by hand or using an old plug wire to prevent the possibility of

crossthreading and damaging the cylinder head bore.

- Carefully tighten the spark plug. If the plug you are installing is equipped

with a crush washer, seat the plug, then tighten about 1⁄4 turn

to crush the washer. If you are installing a tapered seat plug, tighten the

plug to specifications provided by the vehicle or plug manufacturer.

- On all engines except the 2.3L V6, apply a small amount of silicone dielectric

compound to the end of the spark plug lead or inside the spark plug boot to

prevent sticking, then install the boot to the spark plug and push until it

clicks into place. The click may be felt or heard, then gently pull back on

the boot to assure proper contact.

- On 2.3L V6 engines, install the ignition coil as follows:

- Position the ignition coil over the spark plug and press it down firmly

to ensure full engagement.

- Align the mounting holes and install the coil attaching screws. Tighten

the screws to 40–57 inch lbs. (4.5–6.4 Nm).

- Attach the ignition coil 4-pin connector.

- For the front bank of spark plugs, lubricate the sealing washers and

install the charge air cooler. Tighten the attaching nuts to 12–16

ft. lbs. (16–22 Nm).

- For the rear bank of spark plugs, install the solenoid bracket assembly.