- Disconnect the negative battery cable.

- Remove the power steering hose brackets from the cylinder head cover.

- Label and disconnect the spark plug wires and spark plug wire clips.

| Fig. 1: Exploded view of the 1.5L engines camshaft

assemblies

|

- Disconnect the breather tube and PCV valve from the cylinder head cover.

Loosen the cylinder head cover in 2–3 steps. Remove the cylinder head

cover.

- Remove the accessory drive belts, water pump pulley, timing belt covers

and timing belt.

- Remove the distributor.

- Hold the camshaft with a wrench on the cast hexagon, and loosen the camshaft

sprocket mounting bolt. Remove the camshaft sprockets.

| Fig. 2: Front camshaft cap bolts loosening sequence

for the 1.5L engine

|

| Fig. 3: Camshaft cap bolts loosening sequence for

the 1.5L engine

|

- Remove the seal plate.

- Rotate the camshafts clockwise so the cams don't press on the tappets.

- Loosen the front camshaft cap bolts in 5–6 steps, starting on the

two outside bolts and finishing on the two inside bolts. Remove the front

camshaft bolts and caps.

NOTE: Note the location of the numbers on top of the camshaft

caps, so the caps can be reinstalled in their original positions.

- Loosen the camshaft cap bolts in 5–6 steps, in the reverse order of

removal. Remove the camshaft caps.

- Remove the camshafts. Remove the chain and oil seals from the camshafts.

To install:

- Insert the chain adjuster between the camshafts.

- Lubricate the camshaft lobes and journals with clean engine oil and install

the camshafts on the cylinder head. Make sure none of the lobes are located

directly on the tappets. Align the marks on the camshaft gear and the timing

chain.

| Fig. 4: When installing the cams, align the marks

on the camshaft gears with the colored/marked links of the chain

|

| Fig. 5: Apply sealant in the positions shown before

installing the cam caps

|

| Fig. 6: Camshaft cap bolts tightening sequence for

the 1.5L engine

|

- Apply silicone sealant to the cylinder head on the front camshaft caps mating

surface. Do not get sealant on the camshaft journals.

- Install the camshaft bearing caps in their original locations. Hand tighten

the camshaft cap bolts numbered: 5, 7, 2, and 4. Install all the bolts and

tighten, in sequence, in 5–6 steps with a final torque of 100–125

inch lbs. (11–14 Nm).

- Apply clean engine oil to the lips of new camshafts seals. Install the seals

using a suitable seal installer flush with the edge of the camshaft cap.

- Install the seal plate.

- Install the camshaft sprockets, timing belt and timing belt covers. Install

the water pump pulley and accessory drive belts. Adjust the tension.

- Apply silicone sealant to a new cylinder head cover gasket, and install

the gasket on the cylinder head cover.

- Apply silicone sealant to the cylinder head in the area adjacent to the

front camshaft caps.

- Install the distributor.

- Install the cylinder head cover. Tighten the bolts in 2 steps, in reverse

of the loosening sequence, to 61–95 inch lbs. (7–11 Nm).

- Install the power steering hose brackets and tighten the bolts to 88 inch

lbs. (10 Nm). Connect the spark plug wires and clips.

- Connect the breather hose and PCV valve.

- Adjust the valve clearance.

- Adjust the ignition timing and idle speed.

- Connect the negative battery cable, run the engine and check for leaks.

NOTE: The camshaft is removed through the front of the cylinder

head.

- Remove the cylinder head from the vehicle and position in a suitable holding

fixture.

NOTE: Do not lay the cylinder head flat on the head gasket

surface as the valves may be damaged.

- Hold the camshaft with a wrench on the hexagon cast into the front of the

camshaft.

| Fig. 7: Remove the thrust plate (1.6L SOHC engine)

then slide the camshaft out of the cylinder head

|

| Fig. 8: Thrust plate removal for the 1.8L SOHC engine

|

- Remove the sprocket bolt and the sprocket.

- Loosen the rocker arm shaft bolts in 2–3 steps, in the reverse of

the torque sequence. Remove the rocker arm and shaft assemblies.

- Pry out the camshaft seal using a small prybar, being careful not to damage

the camshaft or seal bore.

- Remove the thrust plate at the rear of the cylinder head.

- Carefully slide the camshaft from the cylinder head, being careful not to

damage the cylinder head bearing surfaces.

To install:

- Lubricate the camshaft lobes and journals and the cylinder head bearing

surfaces with clean engine oil.

- Carefully slide the camshaft into the cylinder head, being careful not to

damage the bearing surfaces.

- Install the camshaft thrust plate. On the 1.6L 8-valve engine, tighten the

thrust retaining bolt to 95 in. lbs. (11 Nm). On the 1.6L and 1.8L 16-valve

engines, the thrust plate is held in place by the rocker arm and shaft assembly.

- Lubricate the lip of a new camshaft seal with clean engine oil and install

in the cylinder head, using a seal installer.

- Lubricate the rocker arms and valve stem tips with clean engine oil. Install

the rocker arm and shaft assemblies and tighten the bolts, in 2–3 steps,

in the proper sequence. The final torque should be 21 ft. lbs. (28 Nm) on

the 1.6L and 1.8L engines.

- Install the camshaft sprocket and retaining bolt. Hold the camshaft with

the wrench on the hexagon and tighten the bolt to 45 ft. lbs. (61 Nm).

- Install the cylinder head and the remaining components in the reverse order

of removal.

- Disconnect the negative battery cable.

- Label and disconnect the spark plug wires and remove the spark plugs.

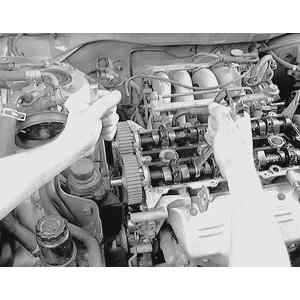

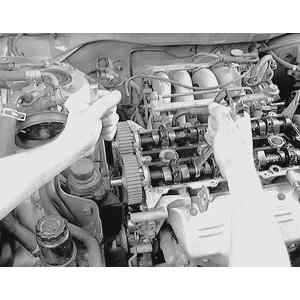

| Fig. 9: To remove the camshafts, first remove the

timing belt, then while holding the cam on the cast hexagon, loosen

the cam sprocket bolt

|

| Fig. 10: Remove the camshaft sprocket bolt and sprocket

|

| Fig. 11: Camshaft cap bolts loosening sequence for

the 1.6L, 1.8L and 2.0L DOHC engines

|

| Fig. 12: Loosen the camshaft cap bolts gradually

in 2–3 steps in sequence

|

| Fig. 13: Once the cap bolts are loose, remove them.

Keep the caps in order and do not mix up intake and exhaust sides

|

- Disconnect the hoses from the cylinder head cover, if equipped.

- Remove the cylinder head cover bolts and remove the cylinder head cover.

On 2.0L engine, loosen the bolts in 2–3 steps in the reverse of the

torque sequence.

| Fig. 14: Also remove the camshaft seals and discard

them. Always install new seals whenever the camshafts are removed

|

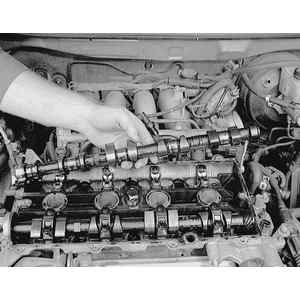

| Fig. 15: Remove the camshafts from the cylinder head.

Again, do not mix up exhaust and intake sides

|

- Remove the timing belt and the distributor.

- Hold the camshaft with a wrench on the hexagon cast into the camshaft. Remove

the sprocket bolts and remove the sprockets.

- Label the caps so they can be reinstalled in their original positions. Loosen

the camshaft cap bolts in 2–3 steps in the reverse of the torque sequence,

then remove the camshaft caps.

- Remove the camshafts. Remove the camshaft oil seals from the camshafts.

To install:

- Lubricate the camshaft journals and lobes with clean engine oil. Install

the camshafts in the cylinder head.

| Fig. 16: Apply silicone sealant to the cylinder head

in the positions shown

|

| Fig. 17: Camshaft cap bolts tightening sequence for

the 1.6L, 1.8L and 2.0L DOHC engine

|

- Apply silicone sealant to the cylinder head on the front camshaft cap mating

surfaces. Do not allow any sealant on the camshaft journals.

- Install the camshaft caps in their original positions. Loosely install the

cap bolts.

- Tighten the camshaft cap bolts in 2–3 steps to 125 inch lbs. (14 Nm)

in the proper sequence.

- Apply clean engine oil to the lip of a new camshaft seal. Push the seal

slightly in by hand. Tap the seal into position, using a seal installer, until

it is flush with the edge of the camshaft cap.

- Turn the camshafts until the dowel pins face straight up. Install the camshaft

sprockets and the sprocket bolts.

- Hold the camshaft with the wrench on the cast hexagon and tighten the sprocket

bolts to 44 ft. lbs. (60 Nm).

- Install the remaining components in the reverse order of removal.

- Disconnect the negative battery cable.

- Disconnect the spark plug wires and hoses from the cylinder head cover and

remove the cylinder head cover.

- Remove the timing belt and the distributor.

- Insert a suitable tool through one of the camshaft sprocket holes to keep

the camshaft from turning. Remove the sprocket bolt and remove the sprocket.

| Fig. 18: Exploded view of the 2.2L engine camshaft

assembly and related components

|

- Remove the front and rear housings from the cylinder head.

- Loosen the rocker arm shaft bolts, in 2–3 steps, in the reverse of

the torque sequence. Remove the rocker arm and shaft assemblies with the bolts.

- Remove the camshaft caps. Label their position prior to removal so they

can be reinstalled in their original locations.

- Remove the camshaft.

To install:

- Lubricate the camshaft journals and lobes with clean engine oil and position

in the cylinder head with the dowel pin facing straight up.

- Apply silicone sealant the cylinder head in the area adjacent to the front

and rear camshaft journals. Do not allow sealant to get on the camshaft journals.

- Install the camshaft caps in their original locations.

- Apply clean engine oil to the valve stem tips and rocker arms.

- Install the rocker arm and shaft assemblies. Tighten the bolts in 2–3

steps to 20 ft. lbs. (26 Nm) in the proper sequence.

NOTE: Make sure the rocker arms or spacers do not get caught

between the shaft and camshaft cap.

- Pry the old oil seal from the front housing. Apply engine oil to the front

housing and a new oil seal and press the seal into the housing.

- Install the front housing using a new gasket. Tighten the bolt and nut to

19 ft. lbs. (25 Nm).

- Install the rear housing using a new gasket. Tighten the bolts/nuts to 19

ft. lbs. (25 Nm).

- Apply silicone sealant at the front and rear corners of the cylinder head

and install the cylinder head cover. Tighten the bolts to 69 inch lbs. (8

Nm). Connect the hoses and spark plug wires.

- Install the camshaft sprocket on the camshaft with the sprocket bolt. Hold

the camshaft sprocket using a suitable tool inserted through a sprocket hole

and tighten the bolt to 48 ft. lbs. (65 Nm).

- Install the timing belt and the remaining components in the reverse order

of removal.

- Properly relieve the fuel system pressure. Disconnect the negative battery

cable and drain the cooling system.

- Remove the timing belt.

- Disconnect the accelerator cable. On 1.8L engine, disconnect the throttle

cable.

- Label and disconnect the spark plug wires.

- Label and disconnect the necessary wiring and hoses.

- Remove the intake manifold and the cylinder head covers.

- Remove the distributor.

- Hold the camshaft with a wrench on the hexagon cast into the camshaft. Remove

the sprocket bolt and remove the sprocket.

| Fig. 19: Front camshaft cap bolt loosening sequence

for the V6 engines

|

| Fig. 20: Camshaft cap bolts loosening sequence for

the V6 engines

|

- Turn the camshaft, using a wrench on the cast hexagon, until the camshaft

knock pin is aligned with the cylinder head marks.

NOTE: Do not remove the camshaft caps when the camshaft

lobe is pressing on a lifter, as the thrust journal support may become damaged.

- Loosen the front camshaft cap bolts in 5–6 steps, in the proper sequence.

Bolt A is only on the right cylinder head. Remove the front

camshaft cap.

- Mark the position of the camshaft caps so they can be reinstalled in their

original locations. Loosen the remaining camshaft cap bolts in 5–6 steps,

in the proper sequence, then remove the caps.

- Remove the camshafts.

To install:

- Lubricate the camshaft journals, lobes and gears with clean engine oil.

Align the intake and exhaust camshaft timing marks and install the camshafts.

NOTE: The thrust plate positions for the right and left

cylinder head camshafts are different.

| Fig. 21: When installing the camshafts, ensure that

the marks on the cam gears are aligned

|

| Fig. 22: Put silicone sealant on the cylinder head

at the positions shown

|

| Fig. 23: Front camshaft cap bolt tightening sequence

for the V6 engines

|

| Fig. 24: Camshaft cap bolt tightening sequence for

the V6 engines

|

- Make sure the camshaft cap and cylinder head surfaces are clean. Apply a

small amount of sealant to the mating surface of the front camshaft cap on

both cylinder heads and the rear exhaust camshaft cap on the left cylinder

head. Do not get any sealant on the camshaft rotating surfaces.

- Install the front camshaft caps and thrust plate caps and tighten the bolts

until the cap seats fully to the cylinder head. Install the remaining camshaft

caps in their original locations and loosely tighten the bolts.

- Tighten the camshaft cap bolts in 5–6 steps to 126 inch lbs. (14 Nm),

in the proper sequence.

- Apply clean engine oil to a new oil seal and the cylinder head. Install

the seal, using a suitable installer. Apply sealant to a new blind cap and

install, using a plastic hammer.

- Install the camshaft sprockets. On the right cylinder head, install the

sprocket so the R mark can be seen and the timing mark aligns

with the camshaft knock pin. On the left cylinder head, install the sprocket

so the L mark can be seen and the timing mark aligns with

the camshaft knock pin.

- Apply clean engine oil to the camshaft sprocket bolt threads and install.

Hold the camshaft with a wrench on the cast hexagon and tighten the sprocket

bolt to 103 ft. lbs. (140 Nm).

- Coat a new gasket with sealant and install onto the cylinder head cover.

Install the cover and tighten the bolts, in sequence, in 2–3 steps,

to 78 inch lbs. (8.8 Nm). Install the ventilation pipe to the left cover.

- Apply clean engine oil to a new O-ring and install on the distributor. Install

the distributor with the blade fitting into the camshaft groove and loosely

tighten the retaining bolt.

- Install the intake manifold using a new gasket. Loosely install the bolts

and nuts. Install the intake manifold stay and tighten the bolts to 19 ft.

lbs. (25 Nm), then tighten the intake manifold bolts/nuts, in 2–3 steps,

to 19 ft. lbs. (25 Nm).

- Connect the wiring, hoses, and the fuel lines.

- Connect the accelerator and, if equipped, throttle valve cables.

- Install the timing belt.

- Connect the negative battery cable. Fill and bleed the cooling system.

- Start the engine and bring to normal operating temperature. Check for leaks.

Check the ignition timing and idle speed.

- Relieve the fuel system pressure. Disconnect the negative battery cable.

- Remove the timing belt covers and timing belt.

- Remove the spacer and O-ring from the front of the camshaft.

- Remove the ignition coils.

- Remove the intake manifold.

- Remove the bolts, in 5–6 steps, using the reverse of the tightening

sequence. Remove the cylinder head cover.

- Remove the camshaft sprockets.

- Turn the camshafts so the knock pins are aligned with the marks on the camshaft

caps. This will reduce the pressure on the adjustment shims.

- Note the markings on the camshaft caps prior to removal, so they can be

reinstalled in the same positions. The right hand (rear) caps are marked with

numbers and the left hand (front) caps are marked with letters.

- Loosen the front camshaft cap bolts in the reverse of the torque sequence,

in 5–6 steps. Remove the front camshaft caps.

- Remove the remaining camshaft cap bolts in the proper sequence. Remove the

caps, being sure to remove the thrust caps last. Do not damage the cylinder

head thrust bearing support.

- Remove the camshafts and oil seals.

- If necessary, remove the lifters and adjustment shims. Identify and mark

each lifter as it is removed so it can be reinstalled in the same position.

To install:

- Apply clean engine oil to the lifters, then install them in their original

positions. Verify that they move smoothly in their bore.

- Install new oil seals on the camshafts. Apply clean engine oil to the camshaft

lobes, journals and supports.

- Install the camshafts so the gear marks align.

- Remove all oil and dirt from the mating surfaces between the front camshaft

cap and the cylinder head.

- Install the thrust caps. Tighten the thrust cap bolts, in 5–6 steps,

until the caps are fully seated on the cylinder head.

- Apply silicone sealant, at a thickness of 0.06–0.09 inch (1.5–2.5mm),

to the cylinder head surface in the area forward of the camshaft gear cavity.

- Install the remaining camshaft caps in their original positions. Tighten

the caps, in sequence, in five equal steps, with the final step being 100–125

inch lbs. (11–14 Nm).

- Apply clean engine oil to the lip of the new camshaft oil seal. Push the

seal in lightly by hand. Tap the seal in evenly with a seal installer (49

F401 337A or equivalent) with a final protrusion of 0–0.02 inch (0–0.5mm).

Tap in a new blind cap.

- Install the camshaft sprockets. Tighten the mounting bolts to 91–103

ft. lbs. (123–140 Nm).

- Measure and adjust valve clearances.

- Remove any sealant and gasket material from the cylinder head cover contact

surfaces.

- Apply silicone sealant to the cylinder head in the area adjacent to the

front and rear camshaft caps. Install a new gasket on the cylinder head.

- Install the cylinder head cover. Tighten the bolts in 5–6 steps, in

sequence, to 44–78 inch lbs. (5–9 Nm).

- Using a new O-ring, install the distributor.

- Install the ignition coils.

- Install the intake manifold.

- Install the spacer, using a new O-ring. Tighten the mounting bolt to 14–18

ft. lbs. (19–25 Nm).

- Install the timing belt and timing belt cover.

- Connect the negative battery cable. Run the engine and check for leaks.

NOTE: For engines which use rocker arms, refer to the Rocker

Arm Removal & Installation procedures earlier in this section.

- Remove the camshaft(s)

- As a precaution, to avoid mix-ups, wipe the oil off the top of all the lash

adjuster/cam followers and, using a permanent type marker, label or number

them. On DOHC engines, also designate whether the adjuster/follower is on

the intake or exhaust side.

| Fig. 25: With the camshafts removed, simply pull

the followers from their bores using a magnet

|

- Use a magnet and pull the lash adjuster/cam follower from its bore.

NOTE: On non-hydraulic cam followers, the adjustment shim

may come out of the follower before the follower is removed from its bore.

If this happens, remove the shim from the magnet and repeat the removal

procedure until the follower is removed. Place the shim back onto the follower.

- Arrange the adjusters/followers, on a clean work surface, in the order that

they are removed.

- Installation is the reverse of the removal procedure.