CAUTION

When draining the coolant, keep in mind that cats and dogs are attracted by

the ethylene glycol antifreeze, and are quite likely to drink any that is left

in an uncovered container or in puddles on the ground. This will prove fatal

in sufficient quantity. Always drain the coolant into a sealable container.

Coolant should be reused unless it is contaminated or several years old.

| Fig. 1: Cylinder head bolt tightening sequence for all

4-cylinder engines

|

| Fig. 2: Cylinder head gasket positioning for the 6-cylinder

engines

|

| Fig. 3: Cylinder head bolt tightening sequence for the

6-cylinder engines

|

NOTE: Before installing the cylinder head, thoroughly clean

and inspect it, especially if the head needed to be removed to replace a blown

gasket. Refer to the Engine Reconditioning procedures, later in this section.

- Disconnect the negative battery cable and remove the engine undercover.

- Remove the air ducts from the air cleaner and throttle body.

- Tag and disconnect the spark plug wires from the spark plugs. Remove the

spark plugs and the distributor cap and wires assembly. Remove the distributor.

- Drain the cooling system and disconnect the radiator and heater hoses.

| Fig. 4: Exploded view of the cylinder head assembly

for the 1990–94 1.6L and 1.8L (except K8) SOHC engines

|

- Disconnect the exhaust pipe and remove the exhaust manifold.

- On DOHC engines, remove the coolant bypass pipe.

- Disconnect the accelerator cable.

| Fig. 5: Exploded view of the cylinder head assembly

for the 1990–94 1.8L (except K8) and 1995 1.6L DOHC engines

|

- Label and disconnect all necessary electrical connections and vacuum hoses.

Disconnect the fuel lines.

- Remove the intake manifold bracket and the intake manifold.

- Remove the cylinder head cover bolts and the cylinder head cover.

- Remove the timing belt cover(s). Rotate the crankshaft, in the normal direction

of rotation, until the No. 1 cylinder piston is at TDC on the compression

stroke. Make sure the timing marks on the crankshaft and camshaft sprocket(s)

are properly aligned and mark the direction of rotation of the belt.

- Loosen the timing belt tensioner and remove the belt. Do not rotate the

crankshaft until the timing belt is reinstalled.

- When everything is disconnected, loosen the cylinder head bolts in the reverse

of the tightening sequence. Remove the bolts and lift the head off the engine.

To install:

- Thoroughly, clean the cylinder head and the block contact surfaces. Examine

the head gasket and check the cylinder head for cracks. Check the cylinder

head for warpage using a feeler gauge and straightedge. The maximum allowable

distortion is 0.004 in. (0.10mm) on 1.8L engine.

- Clean the cylinder head bolts and the threads in the block. Make sure the

bolts turn freely in the block.

- Install a new head gasket on the engine block. Make sure the camshaft sprocket

timing marks are still aligned, as set during the removal procedure. Install

the cylinder head.

- Lubricate the bolt threads and seat surfaces with clean engine oil and install

them. Torque the bolts in 2–3 steps to 56–60 ft. lbs. (75–81

Nm) in the proper sequence.

- Make sure the crankshaft and camshaft sprocket timing marks are aligned,

install the timing belt and set the tension. Carefully rotate the crankshaft

2 turns to make sure the timing marks still line up.

- Apply a thin bead of sealant to the cylinder head cover and install the

new gasket. Install the cover and torque the cover bolts to 78 inch lbs. (9

Nm).

- Install the timing belt cover(s) and tighten the bolts to 95 inch lbs. (11

Nm).

- Use new gaskets and install the manifolds. Torque the intake manifold bolts/nuts

to 19 ft. lbs. (25 Nm) and install the intake manifold bracket. Torque the

exhaust manifold nuts to 34 ft. lbs. (46 Nm).

- Use a new gasket to connect the exhaust pipe and torque the nuts to 34 ft.

lbs. (46 Nm).

- If removed, install the radiator and connect all cooling system hoses. On

DOHC engines, install the coolant bypass pipe.

- Install the distributor, spark plugs, distributor cap and wires.

- Connect all vacuum and fuel system hoses and connect all wiring.

- Connect the accelerator cable and install the air ducts and engine undercover.

- Connect the negative battery cable. Fill and bleed the cooling system. Change

the engine oil.

- Start the engine and bring to normal operating temperature. Check for leaks.

Check the ignition timing and idle speed.

- Relieve the fuel system pressure and disconnect the negative battery cable.

Drain the cooling system.

- Remove the splash shield, fresh air duct and air cleaner assembly.

- Disconnect the accelerator and throttle cables.

- Tag and disconnect the spark plug wires from the spark plugs. Remove the

spark plugs and the distributor cap and wires assembly. Remove the distributor.

- Disconnect the following hoses: Heater, brake vacuum, purge, fuel, water

and upper radiator.

- Label and disconnect the distributor/coil connectors, engine coolant temperature

sensor connector, cooling fan coolant temperature sensor connector and temperature

gauge sensor connector.

- Remove the coolant bypass pipe.

- Remove the accessory drive belts. Remove the power steering pump bolts and

secure the pump aside with mechanics wire, leaving the hoses attached.

- Remove the water pump pulley.

- Remove the alternator bracket nut and bolt and position the bracket aside.

- Disconnect the hoses from the cylinder head cover and loosen the cover bolts

in 5–6 step sequences. Remove the cylinder head cover.

- Remove the timing belt cover(s). Rotate the crankshaft, in the normal direction

of rotation, until the No. 1 cylinder piston is at TDC on the compression

stroke. Make sure the timing marks on the crankshaft and camshaft sprocket(s)

are properly aligned and mark the direction of rotation of the belt.

- Loosen the timing belt tensioner and remove the belt. Do not rotate the

crankshaft until the timing belt is reinstalled.

- Remove the camshaft sprockets and the camshaft.

- Remove the hydraulic lifters. Identify each lifter as it is removed so it

can be reinstalled in the same position. If the lifters are to be reused,

store them upside down in an oil-filled sealed container.

- Disconnect the exhaust pipe and remove the exhaust manifold.

- Remove the intake manifold bracket and the intake manifold.

- Loosen the cylinder head bolts, in 2–3 steps, in sequence. Remove

the bolts and the cylinder head.

To install:

- Thoroughly, clean the cylinder head and the block contact surfaces. Examine

the head gasket and check the cylinder head for cracks. Check the cylinder

head for warpage using a feeler gauge and straightedge. The maximum allowable

distortion is 0.004 in. (0.10mm).

- Clean the cylinder head bolts and the threads in the block. Make sure the

bolts turn freely in the block.

- Install a new head gasket on the engine block. Make sure the camshaft sprocket

timing marks are still aligned, as set during the removal procedure. Install

the cylinder head.

- Lubricate the bolt threads and seat surfaces with clean engine oil and install

them. Torque the bolts in 2–3 steps to 56–60 ft. lbs. (75–81

Nm) in the proper sequence.

- Use new gaskets and install the manifolds. Torque the intake manifold bolts/nuts

to 19 ft. lbs. (25 Nm) and install the intake manifold bracket. Torque the

exhaust manifold nuts to 34 ft. lbs. (46 Nm).

- Use a new gasket to connect the exhaust pipe and torque the nuts to 34 ft.

lbs. (46 Nm).

- Apply clean engine oil to the hydraulic lifters and install them in their

original positions. Make sure they move freely in the bores.

- Install the camshaft and sprockets.

- Make sure the crankshaft and camshaft sprocket timing marks are aligned,

install the timing belt and set the tension. Carefully rotate the crankshaft

2 turns to make sure the timing marks still line up.

- Apply a thin bead of sealant to the cylinder head cover and install the

new gasket. Install the cover and torque the cover bolts to 78 inch lbs. (9

Nm).

- Install the timing belt cover(s) and tighten the bolts to 95 inch lbs. (11

Nm).

- Install the alternator bracket. Tighten the bracket nut and bolt to 19 ft.

lbs. (25 Nm).

- Install the water pump pulley.

- Install the alternator belt and adjust the tension.

- Loosely install the power steering pump through and lockbolts. Connect the

pump pressure switch connector.

- Install the power steering pump belt and adjust the tension. Tighten the

pump through-bolt to 45 ft. lbs. (61 Nm) and the lockbolt to 34 ft. lbs. (46

Nm).

- Install the power steering pump belt shield and tighten the bolts to 86

inch lbs. (9 Nm). Install the power steering hose brackets to the cylinder

head cover, and tighten the bolts to 88 inch lbs. (10 Nm).

- Install the coolant bypass pipe.

- Connect the electrical engine harness connectors.

- Connect the heater, brake vacuum, purge, fuel, water and upper radiator

hoses.

- Install the distributor, spark plugs, distributor cap and wires.

- Connect and adjust the accelerator and throttle cables.

- Install the air ducts, cleaner and splash shield.

- Connect the negative battery cable. Fill and bleed the cooling system. Change

the engine oil.

- Adjust the ignition timing.

- Start the engine and bring to normal operating temperature. Check for leaks.

Check the ignition timing and idle speed.

- Relieve the fuel system pressure and disconnect the negative battery cable.

Drain the cooling system.

- Raise and safely support the vehicle.

- Remove the right front wheel and splash shield.

- Loosen the water pump pulley attaching bolts.

- Remove the power steering belt shield. Loosen the power steering adjusting

bolt, lockbolt and through-bolt and remove the power steering belt.

- Loosen the alternator adjusting bolt and upper mounting bolt. Remove the

alternator belt.

| Fig. 6: Exploded view of the cylinder head assembly

for the 1.5L engine

|

| Fig. 7: Exploded view of the cylinder head assembly

for the 1995–98 1.8L engine

|

- Remove the water pump pulley.

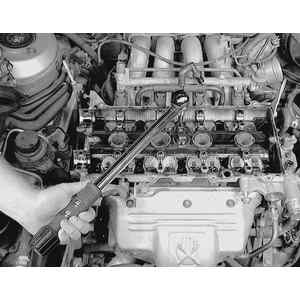

- Using a holder tool, hold the crankshaft pulley and remove the pulley bolt.

Use a suitable puller to remove the pulley, then remove the guide plate.

- Remove the power steering hose brackets from the cylinder head cover. Label

and disconnect the spark plug wires and wire clips.

- Disconnect the breather tube and PCV valve from the cylinder head cover.

Remove the bolts, in 2 steps, in the reverse order of the tightening sequence.

Remove the cylinder head cover.

- Remove the oil dipstick and bracket.

- Remove the timing belt upper cover.

- Use a suitable engine support tool, and remove the number three engine mount

bracket.

- Remove the timing belt middle and lower covers.

- Rotate the crankshaft, in the normal direction of rotation, until the No.

1 cylinder piston is at TDC on the compression stroke. Make sure the timing

marks on the crankshaft and camshaft sprocket(s) are properly aligned and

mark the direction of rotation of the belt.

- Loosen the timing belt tensioner and remove the belt. Do not rotate the

crankshaft until the timing belt is reinstalled.

- Remove air cleaner assembly and front pipe.

- Remove the exhaust manifold.

- Disconnect the accelerator and throttle cables.

- Tag and disconnect the spark plug wires from the spark plugs. Remove the

spark plugs and the distributor cap and wires assembly. Remove the distributor.

- Disconnect the following hoses: Heater, brake vacuum, purge, fuel, water

and upper radiator.

- Label and disconnect the distributor/coil connectors, engine coolant temperature

sensor connector, cooling fan coolant temperature sensor connector, and temperature

gauge sensor connector.

- Remove the camshaft sprockets and the camshaft.

- On the 1.5L engine, remove the tappets. Identify each tappet as it is removed

so it can be reinstalled in the same position.

- On the 1.8L engine, remove the hydraulic lifters. Identify each lifter as

it is removed so it can be reinstalled in the same position. If the lifters

are to be reused, store them upside down in an oil-filled sealed container.

- Remove the intake manifold bracket and the intake manifold.

- Loosen the cylinder head bolts, in 2–3 steps, in sequence. Remove

the bolts and the cylinder head.

To install:

- Thoroughly, clean the cylinder head and the block contact surfaces. Examine

the head gasket and check the cylinder head for cracks. Check the cylinder

head for warpage using a feeler gauge and straightedge. The maximum allowable

distortion is 0.004 in. (0.10mm).

- Clean the cylinder head bolts and the threads in the block. Make sure the

bolts turn freely in the block.

- Install a new head gasket on the engine block. Make sure the camshaft sprocket

timing marks are still aligned, as set during the removal procedure. Install

the cylinder head.

- Lubricate the bolt threads and seat surfaces with clean engine oil and install

them as follows;

- On the 1.5L (Z5D) engines, torque the bolts in 2–3 steps to 13–16

ft. lbs. (17–22 Nm) in the proper sequence. Paint a reference mark

on each bolt head and turn the bolts, in sequence, 90°, and then

an additional 90°.

- On the 1.8L (BPD) engines, torque the bolts in 2–3 steps to 56–60

ft. lbs. (75–81 Nm) in the proper sequence.

- Use new gaskets and install the manifolds. Torque the intake manifold bolts/nuts

to 19 ft. lbs. (25 Nm) and install the intake manifold bracket. Torque the

exhaust manifold nuts to 34 ft. lbs. (46 Nm).

- Use a new gasket to connect the exhaust pipe and torque the nuts to 34 ft.

lbs. (46 Nm).

- Apply clean engine oil to the tappets and install them in their original

positions.

- Install the camshaft and sprockets.

- Make sure the crankshaft and camshaft sprocket timing marks are aligned,

install the timing belt and set the tension. Carefully rotate the crankshaft

2 turns to make sure the timing marks still line up.

- Install the timing belt middle and lower covers, and tighten the bolts to

70–95 inch lbs. (8–11 Nm).

- Install the number three engine mount bracket. Tighten the nut to 70–95

inch lbs. (8–11 Nm), and the bolt to 14–16 ft. lbs. (19–22

Nm). Remove the engine support tool.

- Install the upper timing belt cover and tighten the bolts to 70–95

inch lbs. (8–11 Nm).

- Install the oil dipstick and bracket.

- Apply silicone sealant to the cylinder surface in the area adjacent to the

front camshaft bearing caps. Apply sealant to a new gasket and install it

on the cylinder head cover.

- Install the cylinder head cover and tighten the bolts in 5–6 steps,

in sequence, to 61–95 inch lbs. (7–11 Nm) on the 1.5 (Z5D) engines

and 44–78 inch lbs. (5–9 Nm) on the 1.8L (BPD) engines.

- Install the power steering hose brackets and tighten the bolts to 70–95

inch lbs. (7–11 Nm). Connect the spark plug wires and wire clips. Connect

the breather tube and PCV valve.

- Install the guide plate, crankshaft pulley and pulley bolt. Hold the pulley

with the holder tool and tighten the bolt to 116–122 ft. lbs. (157–166

Nm).

- Install the water pump pulley.

- Install the alternator belt and adjust the tension.

- Install the power steering belt and adjust the tension. Tighten the through-bolt

to 32–44 ft. lbs. (44–60 Nm) and the lockbolt to 24–33 ft.

lbs. (32–46 Nm). Install the power steering belt shield and tighten

the bolts to 86 inch lbs. (9 Nm).

- Install the splash shield and wheel. Lower the vehicle.

- Connect the electrical engine harness connectors.

- Connect the heater, brake vacuum, purge, fuel, water and upper radiator

hoses.

- Install the distributor, spark plugs, distributor cap and wires.

- Connect and adjust the accelerator and throttle cables.

- Install the cleaner.

- Connect the negative battery cable. Fill and bleed the cooling system. Change

the engine oil.

- Adjust the ignition timing.

- Start the engine and bring to normal operating temperature. Check for leaks.

Check the ignition timing and idle speed.

- Relieve the fuel system pressure and disconnect the negative battery cable.

Drain the cooling system.

- Remove the splash shield, fresh air duct and air cleaner assembly.

| Fig. 8: Exploded view of the cylinder head assembly

for the 2.0L engine

|

- Disconnect the accelerator cable.

- Disconnect the following hoses: heater, brake vacuum, purge, fuel, water

and upper radiator.

- Remove the accessory drive belts. Remove the power steering pump bolts and

secure the pump aside with mechanics wire, leaving the hoses attached.

- Remove the alternator bracket nut and bolt and position the bracket aside.

Detach the exhaust pipe from the manifold.

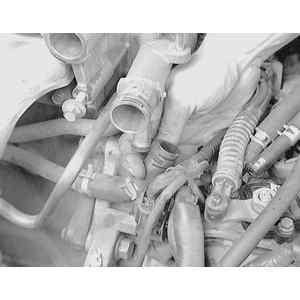

| Fig. 9: To remove the cylinder head, first drain

the coolant, then remove the air intake ducting, valve cover, distributor

and radiator hose

|

| Fig. 10: Also disconnect the water bypass hose .

. .

|

| Fig. 11: . . . as well as the engine wire harness,

fuel lines (arrows) and heater hoses

|

| Fig. 12: If necessary, unbolt the EGR pipe securing

bracket from the engine block

|

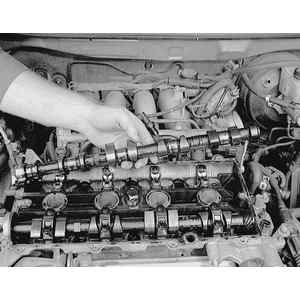

| Fig. 13: Remove the timing belt and camshafts from

the cylinder head

|

- Label and disconnect the spark plug wires. Remove the power steering hose

brackets from the cylinder head cover.

- Label and detach the distributor/coil connectors, engine coolant temperature

sensor connector, cooling fan coolant temperature sensor connector and temperature

gauge sensor connector.

- Disconnect the hoses from the cylinder head cover and loosen the cover bolts

in 5–6 steps, in the reverse order of the tightening sequence. Remove

the cylinder head cover.

- Remove the timing belt cover and the timing belt.

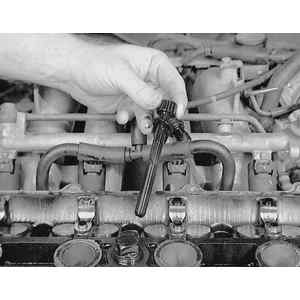

| Fig. 14: Loosen the cylinder head bolts evenly in

2–3 steps following the sequence

|

| Fig. 15: Once all of the cylinder head bolts are

loosened remove them along with their washers

|

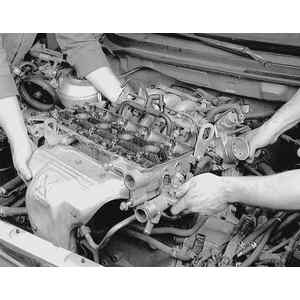

| Fig. 16: With the help of an assistant, lift the

cylinder head off of the engine, complete with intake and exhaust

manifolds

|

| Fig. 17: Remove the old cylinder head gasket . .

.

|

| Fig. 18: . . . and, after stuffing rags in the cylinder

bores, thoroughly clean the gasket mating surfaces

|

- Remove the coolant temperature sensor housing from the cylinder head. Remove

the distributor.

- Remove the camshaft sprockets and the camshaft.

- Remove the hydraulic lifters. Identify each lifter as it is removed so it

can be reinstalled in the same position. If the lifters are to be reused,

store them upside down in an oil-filled sealed container.

- Loosen the cylinder head bolts, in 2–3 steps, in sequence. Remove

the bolts and the cylinder head.

- Clean all gasket mating surfaces. Inspect the cylinder head for damage,

cracks, and water and oil leakage. Check the head gasket surface for distortion

using a straight-edge and feeler gauge. Maximum allowable distortion is 0.004

inch (0.10mm).

To install:

- Position a new cylinder head gasket on the cylinder block, and install the

cylinder head.

- Apply clean engine oil to the bolt threads and seating faces. Install new

cylinder head bolts and tighten in 2–3 steps, in sequence, to 13–16

ft. lbs. (17–22 Nm).

- Paint a mark on the edge of each cylinder head bolt to use as a reference.

Turn each bolt, in sequence, 90 degrees. Again, turn each bolt, in sequence,

an additional 90 degrees.

| Fig. 19: When installing the head, tighten the head

bolts in sequence to the proper specifications

|

- Apply clean engine oil to the hydraulic lifters and install them in their

original positions. Make sure they move freely in the bores.

- Install the camshafts and sprockets. Install the distributor and connect

the distributor/coil connectors.

- Install the timing belt and cover.

- Install a new cylinder head cover gasket on the cylinder head cover. Apply

sealant to the cylinder head surface in the area adjacent to the front camshaft

caps, then install the cover. Tighten the bolts in 5–6 steps, in sequence,

to 61–95 inch lbs. (7–11 Nm).

- Connect the hoses to the cylinder head cover. Connect the spark plug wires.

- Install the exhaust manifold and the alternator bracket. Tighten the bracket

nut and bolt to 19 ft. lbs. (25 Nm).

- Install the alternator belt and adjust the tension.

- Loosely install the power steering pump through and lockbolts. Connect the

pump pressure switch connector.

- Install the power steering pump belt and adjust the tension. Tighten the

pump through-bolt to 45 ft. lbs. (61 Nm) and the lockbolt to 34 ft. lbs. (46

Nm).

- Install the power steering pump belt shield and tighten the bolts to 86

inch lbs. (9 Nm). Install the power steering hose brackets to the cylinder

head cover, and tighten the bolts to 88 inch lbs. (10 Nm).

- Install the coolant temperature sensor housing with a new gasket. Tighten

the bolts to 19 ft. lbs. (25 Nm). Connect the electrical connectors at the

housing.

- Connect and adjust the accelerator cable.

- Connect the heater, brake vacuum, purge, fuel, water and upper radiator

hoses.

- Install the air cleaner assembly, fresh air duct and splash shield.

- Connect the negative battery cable. Fill and bleed the cooling system. Run

the engine and check for proper operation.

- Properly relieve the fuel system pressure.

- Disconnect the negative battery cable and drain the cooling system.

- Disconnect the spark plug wires and remove the spark plugs and the distributor.

- Disconnect the accelerator cable and if equipped, throttle valve cable.

- Disconnect the air intake hose from the throttle body. Disconnect and plug

the fuel lines.

- Remove the upper radiator hose, water bypass hose, heater hose, oil cooler

hose and brake vacuum hose. If equipped with turbocharger, disconnect the

oil cooler hose.

- Remove the 3-way solenoid and EGR solenoid valve assemblies.

- Label and disconnect the wiring and vacuum hoses.

| Fig. 20: Exploded view of the cylinder head assembly

for the 2.2L engine

|

- Remove the vacuum chamber and exhaust manifold shield.

- Remove the EGR pipe, turbocharger oil pipe, if equipped, and exhaust pipe.

- Remove the exhaust manifold. On turbocharged engines, remove the manifold

and turbocharger as an assembly.

- Remove the intake manifold bracket and the intake manifold.

- Remove the air conditioning compressor and bracket and position the compressor

aside, without disconnecting the refrigerant lines.

- Remove the upper timing belt cover.

- To remove the timing belt, perform the following:

- Rotate the crankshaft so the 1 on the camshaft sprocket

is aligned with the timing mark on the front housing.

- When timing marks are aligned, loosen the timing belt tensioner lock

bolt. Pull the tensioner outward as far as possible and temporarily tighten

the lock bolt.

- Lift the timing belt from the camshaft pulley and position it aside.

- Remove the cylinder head cover and gasket.

- Loosen the cylinder head bolts in the reverse of the tightening sequence,

and remove the cylinder head and head gasket.

- Thoroughly clean all gasket mating surfaces. Check the cylinder head for

cracks or other damage. Check the cylinder head for warpage using a feeler

gauge and straightedge. The maximum allowable distortion is 0.006 in. (0.15mm).

19.

Inspect the cylinder head bolts for damaged threads and make sure they

turn freely in the threads in the block.

To install:

- Position a new cylinder head gasket on the engine block and install the

cylinder head.

- Lubricate the bolt threads and seat surfaces with clean engine oil and install

them. Torque the bolts in 2–3 steps to 59–64 ft. lbs. (80–86

Nm), in the proper sequence.

- Apply sealant to the 4 corners of the cylinder head and install the cover

with a new gasket. Torque the cover bolts to 69 inch lbs. (8 Nm).

- Make sure the camshaft sprocket and front housing timing marks are aligned

and install the timing belt. Set the tension and carefully rotate the crankshaft

2 turns to make sure the timing marks still line up. Install the timing belt

cover.

- Use a new gasket and install the intake manifold. Torque the nuts/bolts

to 22 ft. lbs. (30 Nm). Install the intake manifold bracket.

- Use new gaskets and install the exhaust manifold. Torque the nuts to 36

ft. lbs. (49 Nm). On turbocharged engines, connect the turbocharger oil line.

- Connect the exhaust pipe with a new gasket and torque the nuts to 34 ft.

lbs. (46 Nm).

- Install the EGR pipe, exhaust manifold shield and vacuum chamber. Install

the EGR solenoid and 3-way solenoid.

- Connect all the coolant, vacuum and fuel system hoses. Connect the air intake

hose to the throttle body.

- Install the distributor and spark plugs and connect all wiring

- Connect the accelerator cable.

- Connect the negative battery cable. Fill and bleed the cooling system. Change

the engine oil.

- Start the engine and bring to normal operating temperature. Check for leaks.

Check the ignition timing and idle speed.

- Relieve the fuel system pressure and disconnect the negative battery cable.

Drain the cooling system.

- Remove the fresh air duct and the air cleaner assembly.

- If additional clearance space is needed, remove the battery.

- Disconnect the accelerator cable.

- Disconnect the wiring harness from the cylinder heads.

- Disconnect the fuel, heater and vacuum hoses.

| Fig. 21: Exploded view of the cylinder head assemblies

for the 1.8L (K8) and 2.5L engines

|

- Remove the intake manifold.

- Remove the distributor.

- Disconnect the ventilation pipe from the left cylinder head cover, remove

the bolts and remove the cylinder head covers.

- Remove the timing belt covers and the timing belt.

- Remove the camshafts. Remove the 3 bolts and the seal plate from the front

of the engine.

- Remove the upper radiator hose. Raise and safely support the vehicle.

- Disconnect the oxygen sensor connectors. Remove the exhaust pipe-to-manifold

nuts and lower the exhaust pipes. Lower the vehicle.

- Remove the hydraulic lifters. Identify each lifter as it is removed so it

can be reinstalled in the same position. If the lifters are to be reused,

store them upside down in an oil-filled, sealed container.

- Loosen the cylinder head bolts, in 2–3 steps, in the reverse order

of the torque sequence. Remove the bolts and remove the cylinder heads.

- Clean all gasket mating surfaces. Inspect the cylinder head for damage,

cracks, and water and oil leakage. Check the head gasket surface for distortion

using a straight-edge and feeler gauge. Maximum allowable distortion is 0.004

in. (0.10mm).

To install:

- Position NEW head gaskets on the cylinder block. The gaskets cannot be interchanged

between sides and are marked R and L for right and left side.

- Install the cylinder heads. Apply clean engine oil to the threads of new

cylinder head bolts and install. Tighten the cylinder head bolts in 2–3

steps, in sequence, to 17–19 ft. lbs. (23–26 Nm).

- Paint a mark on the edge of each cylinder head bolt to use as a reference.

Turn each bolt, in sequence, 90 degrees. Again, turn each bolt, in sequence,

an additional 90 degrees.

- Apply clean engine oil to the hydraulic lifters and install them in their

original positions. Make sure they move freely in the bores.

- Install the camshafts. Raise and safely support the vehicle.

- Connect the exhaust pipes to the manifolds and tighten the nuts to 41 ft.

lbs. (55 Nm). Connect the oxygen sensor connectors. Lower the vehicle.

- Install the timing belt and timing belt covers.

- Apply sealant to the cylinder head surface in the area of the front and

rear camshaft caps. Install new gaskets and install the cylinder head covers.

Tighten the bolts in 5–6 steps, in sequence, to 44–78 inch lbs.

(5–9 Nm).

- Install the intake manifold using new gaskets. Tighten the mounting bolts

to 14–18 ft. lbs. (19–25 Nm).

- Install the distributor:

- Apply clean engine oil to a new O-ring, and position it on the distributor.

- Apply clean engine oil to the drive blade. Install the distributor with

the blade fit into the camshaft groove.

- Hand tighten the mounting bolts.

- Connect the vacuum, heater and fuel hoses.

- Connect the wiring harness to the cylinder heads.

- Connect and adjust the accelerator cable.

- If removed, install the battery.

- Install the air cleaner assembly and the fresh air duct.

- Connect the negative battery cable. Fill and bleed the cooling system. Adjust

the ignition timing and idle speed. Run the engine and check for proper operation.

- Relieve the fuel system pressure. Disconnect the negative battery cable.

- Drain the engine coolant.

- Raise and safely support the vehicle.

- Disconnect the oxygen sensor connectors. Remove the exhaust pipe-to-manifold

nuts and lower the exhaust pipes.

- Remove the right-hand three-way catalytic converter. Lower the vehicle.

| Fig. 22: Exploded view of the cylinder head assemblies

and related components for the 2.3L engine

|

- Remove the Lysholm compressor (supercharger).

- Remove the intake manifold.

- Remove the timing belt covers and timing belt.

- Remove the spacer and O-ring from the front of the camshaft.

- Remove the ignition coils.

- Remove the cylinder head cover mounting bolts, in 5–6 steps, using

the reverse of the tightening sequence. Remove the cylinder head cover.

- Remove the camshaft sprockets.

- Turn the camshafts so the knock pins are aligned with the marks on the camshaft

caps. This will reduce the pressure on the adjustment shims.

- Note the markings on the camshaft caps prior to removal, so they can be

reinstalled in the same positions. The right hand (rear) caps are marked with

numbers and the left hand (front) caps are marked with letters.

- Loosen the front camshaft cap bolts in sequence, in 5–6 steps. Remove

the front camshaft caps.

- Remove the remaining camshaft cap bolts in the proper sequence. Remove the

caps, being sure to remove the thrust caps last. Do not damage the cylinder

head thrust bearing support.

- Remove the camshafts and oil seals.

- Remove the lifters and adjustment shims. Identify and mark each lifter as

it is removed so it can be reinstalled in the same position.

- Remove the lower radiator hose and water inlet pipe.

- Remove the Lysholm compressor bracket.

- Remove the alternator bracket bolt to gain additional clearance.

- Remove the rubber insulator from the left-hand cylinder head.

- Temporarily install the number three engine mount, which was removed with

the timing belt, to support the engine. Remove the engine support device.

- Loosen the cylinder head bolts, in 2–3 steps, in the reverse order

of the torque sequence. Remove the bolts and remove the cylinder heads.

- Remove the oil control plug O-rings.

- Clean all gasket mating surfaces. Inspect the cylinder head for damage,

cracks, and water and oil leakage. Check the head gasket surface for distortion

using a straight-edge and feeler gauge. Maximum allowable distortion is 0.004

inch (0.10mm).

To install:

- Apply clean engine oil to the O-rings, and install them onto the oil control

plugs.

- Position new head gaskets on the cylinder block. The gaskets cannot be interchanged

between sides and are marked R and L for

right and left side.

- Install the cylinder heads. Apply clean engine oil to the threads of new

cylinder head bolts and install. Tighten the cylinder head bolts in 2–3

steps, in sequence, to 17–19 ft. lbs. (23–26 Nm).

- Paint a mark on the edge of each cylinder head bolt to use as a reference.

Turn each bolt, in sequence, 90 degrees. Again, turn each bolt, in sequence,

an additional 90 degrees.

- Install the rubber insulator onto the left-hand cylinder head.

- Fit the knock sensor harness into the drill hole on the cylinder block.

Pass the harness under the rubber insulator.

- Install an engine support device, and remove the number three engine mount.

- Install the alternator bracket bolt. Tighten the mounting bolt to 12–16

ft. lbs. (16–22 Nm).

- Install the Lysholm compressor bracket. Tighten the mounting bolts to 14–18

ft. lbs. (19–25 Nm).

- Install the water inlet pipe. Tighten the mounting bolts to 14–18

ft. lbs. (19–25 Nm). Install the lower radiator hose.

- Apply clean engine oil to the lifters, then install them in their original

positions. Verify that they move smoothly in their bore.

- Install new oil seals on the camshafts. Apply clean engine oil to the camshaft

lobes, journals and supports.

- Install the camshafts so the gear marks align.

- Remove all oil and dirt from the mating surfaces between the front camshaft

cap and the cylinder head.

- Install the thrust caps. Tighten the thrust cap bolts, in 5–6 steps,

until the caps are fully seated on the cylinder head.

- Apply silicone sealant, at a thickness of 0.06–0.09 inch (1.5–2.5mm),

to the cylinder head surface in the area forward of the camshaft gear cavity.

- Install the remaining camshaft caps in their original positions. Tighten

the caps, in sequence, in five equal steps, with the final step being 100–125

inch lbs. (11–14 Nm).

- Apply clean engine oil to the lip of the new camshaft oil seal. Push the

seal in lightly by hand. Tap the seal in evenly with a seal installer (49

F401 337A or equivalent) with a final protrusion of 0–0.02 inch (0–0.5mm).

Tap in a new blind cap.

- Install the camshaft sprockets. Tighten the mounting bolts to 91–103

ft. lbs. (123–140 Nm).

- Measure and adjust valve clearances.

- Remove any sealant and gasket material from the cylinder head cover contact

surfaces.

- Apply silicone sealant to the cylinder head in the area adjacent to the

front and rear camshaft caps. Install a new gasket on the cylinder head.

- Install the cylinder head cover. Tighten the bolts in 5–6 steps, in

sequence, to 44–78 inch lbs. (5–9 Nm).

- Using a new O-ring, install the distributor.

- Install the ignition coils.

- Install the spacer, using a new O-ring. Tighten the mounting bolt to 14–18

ft. lbs. (19–25 Nm).

- Install the timing belt and timing belt cover.

- Install the intake manifold.

- Install the Lysholm compressor (supercharger).

- Raise and safely support the vehicle.

- Install the right-hand three-way catalytic converter.

- Connect the exhaust pipes to the manifolds and tighten the nuts to 28–38

ft. lbs. (38–51 Nm). Connect the oxygen sensor connectors. Lower the

vehicle.

- Connect the negative battery cable.

- Fill and bleed the coolant system.

- Run the engine and check for leaks.