CAUTION

When draining the coolant, keep in mind that cats and dogs are attracted by

the ethylene glycol antifreeze, and are quite likely to drink any that is left

in an uncovered container or in puddles on the ground. This will prove fatal

in sufficient quantity. Always drain the coolant into a sealable container.

Coolant should be reused unless it is contaminated or several years old.

- Properly relieve the fuel system pressure. Disconnect the negative battery

cable and drain the cooling system.

- Disconnect the air intake hose from the throttle body. Remove the hose,

resonator(s) and air cleaner assembly.

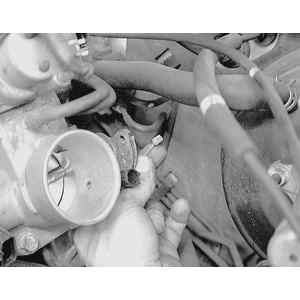

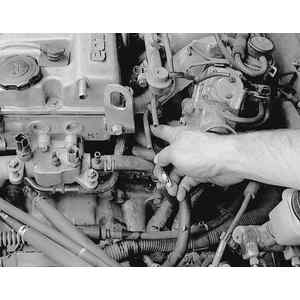

| Fig. 1: To remove the intake manifold, first remove

the air intake hoses, then disconnect the throttle cable from the

throttle body . . .

|

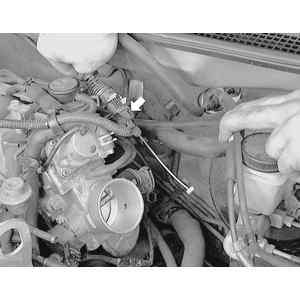

| Fig. 2: . . . as well as the throttle cable housing

(arrow) from its retaining bracket

|

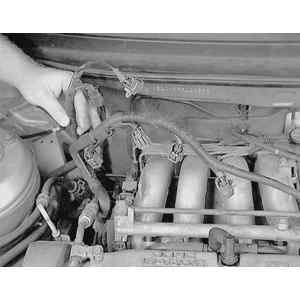

| Fig. 3: Next, disconnect the fuel lines (arrows),

and label and detach all vacuum hose connections . . .

|

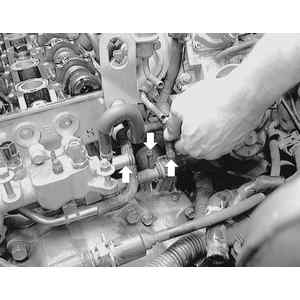

| Fig. 4: . . . along with the electrical wire harness

connections on the intake manifold

|

- Disconnect the accelerator and, if equipped, the cruise control cable. Disconnect

and plug the fuel lines.

- Label and disconnect all necessary vacuum hoses and electrical connectors.

Disconnect the coolant hoses.

- Disconnect the EGR tube, if equipped.

| Fig. 5: Detach any throttle body pre-heat coolant

hoses from the intake manifold

|

| Fig. 6: Ensure that any coolant hoses connected to

the intake are disconnected, as their can be quite a few of them (arrows)

|

| Fig. 7: From underneath, remove the intake manifold

support, then remove the intake manifold attaching bolts and nuts

|

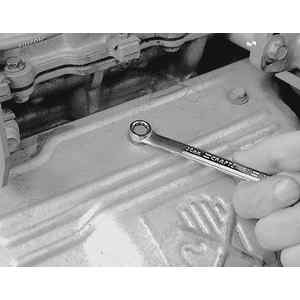

| Fig. 8: Some bolts may prove difficult to reach.

Switch to various wrenches and positions will help

|

| Fig. 9: Once all fasteners and connections are removed,

slide the intake backwards off its mounting studs then remove it from

the vehicle

|

- If necessary, remove the air valve and remove the fuel rail attaching bolts.

Remove the fuel rail and injectors as an assembly.

- From below, remove the intake manifold support bracket.

- If necessary, remove the bolt retaining the dipstick tube bracket to the

intake manifold.

- If necessary, unbolt the vacuum solenoid bracket from the manifold and position

it aside. This will afford better access to the intake attaching nuts/bolts.

- Remove the intake manifold-to-cylinder head bolts/nuts and remove the intake

manifold assembly.

- If necessary, remove the throttle body and separate the intake manifold

upper and lower halves.

To install:

- Clean all gasket mating surfaces.

- If separated, connect the upper and lower intake manifolds using a new gasket.

Tighten the nuts/bolts to 19 ft. lbs. (25 Nm). If removed, install the throttle

body using a new gasket. Tighten the retaining nuts/bolts to 19 ft. lbs. (25

Nm).

| Fig. 10: Thoroughly clean the gasket mating surfaces

of all traces of the old gasket

|

| Fig. 11: Intake manifold tightening sequence

|

- Install the intake manifold assembly to the cylinder head using a new gasket.

Tighten the nuts/bolts to 19 ft. lbs. (25 Nm) on all except 2.2L engine. On

2.2L engine, tighten to 22 ft. lbs. (30 Nm).

NOTE: On all except the 2.2L engine, torque the intake

manifold-to-cylinder head bolts in the proper sequence. On the 2.2L engine,

tighten the bolts in the center of the manifold first and work outwards

toward the ends.

- If equipped, install the bolt retaining the dipstick tube to the intake

manifold.

- Install the intake manifold bracket. Tighten the attaching nuts/bolts to

38 ft. lbs. (52 Nm) for the 2.0L and 2.2L engine and 19 ft. lbs. (25 Nm) on

the 1.6L and 1.8L engines.

- If removed, install the fuel rail and injector assembly on the intake manifold

using new insulators. Tighten the fuel rail mounting bolts to 19 ft. lbs.

(25 Nm). Install the air valve and tighten the bolts to 57 inch lbs. (5.5

Nm).

- Connect the EGR tube, if equipped. Connect the coolant and vacuum hoses,

electrical connectors and fuel lines.

- Connect the accelerator cable. Install the air cleaner assembly, if removed,

and connect the air intake tube to the throttle body.

- Connect the negative battery cable. Fill and bleed the cooling system.

- Start the engine and bring to normal operating temperature. Check for leaks.

Check the idle speed.

- Relieve the fuel system pressure, and disconnect the negative battery cable.

Drain the cooling system.

- Disconnect the mass air flow sensor electrical connector. Remove the air

ducts, air cleaner assembly, mass air flow sensor and resonance chamber.

| Fig. 12: Exploded view of the intake manifold and

related components for the 1.5L engine

|

| Fig. 13: Exploded view of the 1.8L (except K8) engine

intake manifold and related components

|

- Disconnect the throttle and accelerator cables. Disconnect and plug the

fuel lines.

- Remove the throttle body as follows:

- Disconnect the coolant hoses.

- Label and disconnect the electrical connectors for the idle air control

valve and the throttle position sensor.

- Remove the mounting bolts/nuts from the throttle body, and remove the

throttle body from the vehicle.

- Label and disconnect the vacuum lines at the intake manifold.

- Remove the dynamic chamber (upper intake manifold).

- Disconnect and plug the fuel hoses from the fuel rail.

- Label and disconnect the electrical connectors for the fuel injectors.

- On some models you may need to remove the fuel rail with the injectors connected.

- On the 1.5L engine, remove the EGR pipe from the intake manifold. Remove

the EGR and pressure regulator control (PRC) solenoid valve brackets.

- Remove the intake manifold support bracket.

- Remove the bolts and nuts, and remove the intake manifold.

To install:

- Clean all gasket mating surfaces.

- Install the intake manifold, using a new gasket. Tighten the nuts and bolts

to 14–18 ft. lbs. (19–25 Nm).

- Attach the EGR pipe to the manifold and install the intake manifold support

bracket. Tighten the support bracket bolts to 38 ft. lbs. (51 Nm).

- If removed, install the EGR and pressure regulator control (PRC) solenoid

valve brackets.

- Install the fuel rail and injector assembly. Connect the electrical connectors

to the injectors, and the fuel lines to the rail.

- Install the upper intake manifold to the intake manifold using new gaskets.

Tighten the nuts to 14–18 ft. lbs. (19–25 Nm).

- Install the throttle body, using a new mounting gasket. Tighten the mounting

bolts to 14–18 ft. lbs. (19–25 Nm).

- Connect the electrical connectors for the idle air control valve and the

throttle position sensor.

- Connect the vacuum and coolant lines.

- Connect and adjust the throttle and accelerator cables.

- Connect the fuel lines.

- Install the resonance chamber. Install the air cleaner assembly, mass air

flow sensor and ducts. Connect the mass air flow sensor connector.

- Connect the negative battery cable. Fill and bleed the cooling system. Run

the engine and check for leaks.

- Relieve the fuel system pressure and disconnect the negative battery cable.

Drain the cooling system.

- Disconnect the mass air flow sensor electrical connector. Remove the air

ducts, air cleaner assembly and resonance chamber.

- Remove the fuel line mounting bracket and disconnect the throttle cable.

Disconnect and plug the fuel lines.

| Fig. 14: Exploded view of the intake manifold for

the 1995 1.6L engine

|

- Remove the throttle body as follows:

- Disconnect the coolant hoses.

- Label and disconnect the electrical connectors for the idle air control

valve and the throttle position sensor.

- Remove the mounting bolts/nuts from the throttle body, and remove the

throttle body from the vehicle.

- Label and disconnect the vacuum lines at the intake manifold.

- Remove the bypass air control (BAC) valve, variable inertia charging system

(VICS) solenoid valve, pressure regulator control (PRC) solenoid valves, and

the EGR solenoid vent and vacuum valves from the intake manifold.

- Disconnect and plug the fuel hoses from the fuel rail.

- Label and disconnect the electrical connectors for the fuel injectors.

- Remove the fuel rail with the injectors connected.

- Remove the intake manifold support bracket and remove the EGR pipe from

the intake manifold.

- Lower the vehicle. Remove the bolts and nuts, and remove the intake manifold.

To install:

- Clean all gasket mating surfaces.

- Install the intake manifold, using a new gasket. Tighten the nuts and bolts

to 16–22 ft. lbs. (22–30 Nm).

- Raise and safely support the vehicle.

- Attach the EGR pipe to the manifold and install the intake manifold support

bracket. Tighten the support bracket bolts to 38 ft. lbs. (51 Nm).

- Install the fuel rail and injector assembly. Connect the electrical connectors

to the injectors, and the fuel lines to the rail.

- Install the bypass air control (BAC) valve, variable inertia charging system

(VICS) solenoid valve, pressure regulator control (PRC) solenoid valves, and

the EGR solenoid vent and vacuum valves to the intake manifold.

- Install the throttle body, using a new mounting gasket. Tighten the mounting

bolts to 14–18 ft. lbs. (19–25 Nm).

- Connect the electrical connectors, vacuum lines and coolant lines.

- Connect the throttle cable and the fuel lines. Install the fuel line mounting

bracket and tighten the bolt to 97 inch lbs. (11 Nm).

- Install the resonance chamber. Install the air cleaner assembly and ducts.

Connect the mass air flow sensor connector.

- Connect the negative battery cable. Fill and bleed the cooling system. Run

the engine and check for leaks.

- Properly relieve the fuel system pressure.

- Disconnect the negative battery cable and drain the cooling system.

- On MX-3, remove the upper strut bar.

| Fig. 15: Exploded view of the intake manifold assembly

for the 1.8L and 2.5L engines

|

- Remove the air cleaner assembly and ducts.

- Disconnect the accelerator cable. Label and disconnect the necessary electrical

connectors and vacuum hoses.

- Disconnect and plug the fuel lines. Disconnect the coolant hose from the

air bypass valve.

- Remove the intake manifold support bracket. Remove the intake manifold-to-cylinder

head bolts and remove the intake manifold.

- If necessary, remove the throttle body and air intake pipe from the manifold.

- Check the intake manifold for cracks or other damage. Check the surface

of the cylinder heads and intake manifold for warpage using a straightedge.

Replace the intake manifold, as necessary.

To install:

- Clean all gasket mating surfaces.

- If removed, install the throttle body using new gaskets. Tighten the nuts/bolts

to 19 ft. lbs. (25 Nm).

- If removed, apply clean engine oil to new O-rings and install the air intake

pipe to the intake manifold. Tighten the bolts to 95 inch lbs. (10.8 Nm).

On 1.8L engine, the bolts must be tightened in the proper sequence.

- Position new gaskets and install the intake manifold to the cylinder head.

Install the mounting bolts and tighten, in 2–3 steps, to 19 ft. lbs.

(25 Nm), working from the center toward the ends of the manifold.

- Install the intake manifold bracket and tighten the bolts to 19 ft. lbs.

(25 Nm).

- Connect the coolant hose to the air bypass valve. Connect the fuel lines.

- Connect the vacuum hoses and electrical connectors. Connect the accelerator

cable.

- Install the air cleaner assembly and ducts. On MX-3, install the upper strut

bar.

- Connect the negative battery cable. Fill and bleed the cooling system.

- Start the engine and bring to normal operating temperature. Check for leaks.

Check the idle speed.

- Relieve the fuel system pressure, and disconnect the negative battery cable.

- Drain the cooling system.

- Remove the dynamic chamber cover.

- Remove the charge air cooler air duct.

- Label and disconnect the vacuum hoses and electrical connectors from the

air cleaner housing. Remove the air cleaner assembly.

- Remove the air and fresh air ducts.

| Fig. 16: Exploded view of the intake manifold assembly

for the 2.3L engine — part 1 of 2

|

| Fig. 17: Exploded view of the intake manifold assembly

for the 2.3L engine — part 2 of 2

|

- Remove the mass air flow sensor and the air intake hose from the throttle

body.

- Remove the resonator.

- Remove the right-hand charge air cooler.

- Remove the left-hand charge air cooler.

- Disconnect the accelerator cable.

- Label and disconnect the necessary vacuum hoses from the rear of the intake

manifold and EGR valve.

- Remove the EGR valve.

- Remove the air intake pipe assembly.

- Remove the charge air cooler pipe.

- Disconnect and plug the fuel supply line at the fuel rails and discard the

copper crush washers. Disconnect the fuel and vacuum lines from the fuel pressure

regulator.

- Disconnect and plug the coolant hoses.

- Remove the harness from the intake manifold.

- Remove the intake manifold mounting nuts and bolts in 2–3 steps, then

remove the intake manifold.

- Label and disconnect the fuel hoses and electrical connectors from the throttle

body. Remove the throttle body.

To install:

- Clean all gasket mating surfaces.

- Install the throttle body. Tighten the nuts and bolts to 14–18 ft.

lbs. (19–25 Nm), and connect the fuel hoses and electrical connectors.

- Position new gaskets and install the intake manifold. Tighten the nuts and

bolts in 2–3 steps, from the center to the ends, to 14–18 ft.

lbs. (19–25 Nm).

- Install the harness onto the intake manifold.

| Fig. 18: Intake manifold bolt tightening sequence

for the 2.3L engine

|

- Unplug and connect the coolant hoses.

- Connect the fuel and vacuum lines to the fuel pressure regulator. Connect

the fuel supply line to the fuel rail, using new copper crush washers.

- Install the charge air cooler pipe.

- Position the air intake pipe assembly using new gaskets. Hand tighten the

nuts and bolts in the order shown in the graphic until the air intake pipe

contacts the intake manifold. Verify that the rubber gaskets are not twisted

or distorted. Tighten the bolts markedA to 70–95 inch lbs. (8–11

Nm), and all others, in sequence, to 14–18 ft. lbs. (19–25 Nm).

- Install the EGR valve using a new gasket.

- Connect the vacuum hoses to the intake manifold and EGR valve.

- Connect and adjust the accelerator cable.

- Using new gaskets, position the left and right-hand charge air coolers.

Hand tighten the nuts and bolts in the order shown in the graphic until the

air intake pipes and charge air coolers contact the intake manifold. Verify

that the rubber gaskets are not twisted or distorted. Tighten the bolts marked A to

44–78 inch lbs. (5–9 Nm). Tighten the bolts marked B to

70–95 inch lbs. (8–11 Nm), and all others, in sequence, to 14–18

ft. lbs. (19–25 Nm).

- Install the resonator. Tighten the nuts and bolts to 12–16 ft. lbs.

(16–22 Nm)

- Install the air intake hose onto the throttle body. Install the mass air

flow sensor.

- Install the fresh air and air ducts.

- Install the air cleaner assembly and connect the vacuum hoses and electrical

connectors to the air cleaner housing.

- Install the charge air cooler air duct. Tighten the mounting bolts to 70–95

inch lbs. (8–11 Nm).

- Install the dynamic chamber cover.

- Connect the negative battery cable.

- Fill and bleed the cooling system. Run the engine and check for leaks.