These vehicles use several different types of joints. Engine size, transaxle type, whether the joint is an inboard or outboard joint, even which side of the vehicle is being serviced could make a difference in joint type. Be sure to properly identify the joint before attempting joint or boot replacement. Look for identification numbers at the large end of the boots and/or on the end of the metal retainer bands.

The 3 types of joints used are the Birfield Joint, (B.J.), the Tripod Joint (T.J.) and the Double Offset Joint (D.O.J.).

NOTE: Do not disassemble a Birfield joint. Service with a new joint or clean and repack using a new boot kit.

The distance between the large and small boot bands is important and should be checked prior to and after boot service. This is so the boot will not be installed either too loose or too tight, which could cause early wear and cracking, allowing the grease to get out and water and dirt in, leading to early joint failure.

NOTE: The driveshaft joints use special grease; do not add any grease other than that supplied with the kit.

To Remove:

NOTE: The Double Offset Joint (D.O.J.) is bigger than other joints and, in these applications, is normally used as an inboard joint.

- Remove the halfshaft from the vehicle.

- Side cutter pliers can be used to cut the metal retaining bands. Remove the boot from the joint outer race.

- Locate and remove the large circlip at the base of the joint. Remove the outer race (the body of the joint).

- Remove the small snap ring and take off the inner race, cage and balls as an assembly. Clean the inner race, cage and balls without disassembling.

- If the boot is to be reused, wipe the grease from the splines and wrap the splines in vinyl tape before sliding the boot from the shaft.

- Remove the inner (D.O.J.) boot from the shaft. If the outer (B.J.) boot is to be replaced, remove the boot retainer rings and slide the boot down and off of the shaft at this time.

To Install:

NOTE: Be sure to tape the shaft splines before installing the boots. Fill the inside of the boot with the specified grease. Often the grease supplied in the replacement parts kit is meant to be divided in half, with half being used to lubricate the joint and half being used inside the boot.

- Install the cage onto the halfshaft so the small diameter side of the cage is installed first. With a brass drift pin, tap lightly and evenly around the inner race to install the race until it comes into contact with the rib of the shaft. Apply the specified grease to the inner race and cage and fit them together. Insert the balls into the cage.

- Install the outer race (the body of the joint) after filling with the specified grease. The outer race should be filled with this grease.

- Tighten the boot bands securely. Make sure the distance between the boot bands is correct.

- Install the halfshaft to the vehicle.

To Remove:

- Disconnect the negative battery cable. Remove the halfshaft.

- Use side cutter pliers to remove the metal retaining bands from the boot(s) that will be removed. Slide the boot from the T.J. case.

- Remove the snap ring and the tripod joint spider assembly from the halfshaft. Do not disassemble the spider and use care in handling.

- If the boot is be reused, wrap vinyl tape around the spline part of the shaft so the boot(s) will not be damaged when removed. Remove the dynamic damper, if used, and the boots from the shaft.

To Install:

- Double check that the correct replacement parts are being installed. Wrap vinyl tape around the splines to protect the boot and install the boots and damper, if used, in the correct order.

- Install the joint spider assembly to the shaft and install the snap ring.

- Fill the inside of the boot with the specified grease. Often the grease supplied in the replacement parts kit is meant to be divided in half, with half being used to lubricate the joint and half being used inside the boot. Keep grease off the rubber part of the dynamic damper (if used).

- Secure the boot bands with the halfshaft in a horizontal position. Make sure distance between boot bands is correct.

- Install the halfshaft to the vehicle and reconnect the negative battery cable.

| Check the CV-boot for wear

|

| Removing the outer band from the CV-boot

|

| Removing the inner band from the CV-boot

|

| Removing the CV-boot from the joint housing

|

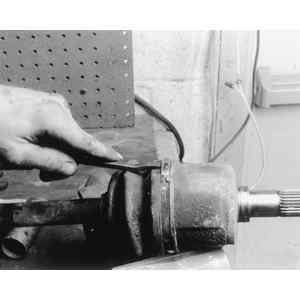

| Clean the CV-joint housing prior to removing boot

|

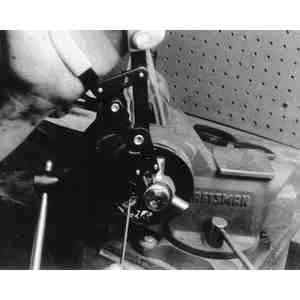

| Removing the CV-joint housing assembly

|

| Removing the CV-joint

|

| Inspecting the CV-joint housing

|

| Removing the CV-joint outer snap ring

|

| Checking the CV-joint snap ring for wear

|

| CV-joint snap ring (typical)

|

| Removing the CV-joint assembly

|

| Removing the CV-joint inner snap ring

|

| Installing the CV-joint assembly (typical)

|