- Drain the cooling system and remove the air cleaner assembly. Remove the

oil dipstick.

- Disconnect the following:

- Throttle and choke linkage

- Fuel line(s)

- PCV valve hose

- Fuel and fuel pump hoses

- Heater hoses

- Distributor vacuum line

- Ventilation valve hose (at the manifold)

- Air pump hose at the anti-afterburn valve

- Brake vacuum hose

- Canister hoses

- Engine harness connectors

- Spark plug wires

- Remove the following components as required to gain access to the intake

manifold:

- Distributor

- Spark plugs

- Carburetor secondary air pipe manifold assembly

- Front engine hanger and ground wire

- Upper radiator hose and coolant bypass hose with mounting bracket

- Unfasten manifold attaching bolts and remove the manifold and gasket from

the cylinder head.

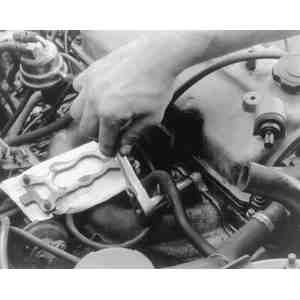

| Fig. 1: Remove the bolts securing the intake manifold

to the cylinder head (note that the carburetor may be left installed

on most models)

|

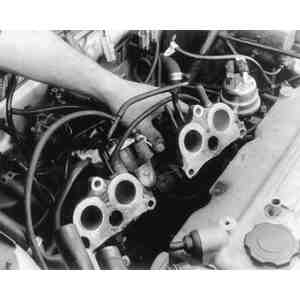

| Fig. 2: Withdraw the intake manifold from the cylinder

head

|

- Cover the ports on the cylinder block to prevent any foreign objects from

falling into the engine.

To install:

- Replace the gaskets, making sure all surfaces are clean and smooth. Check

manifold for warpage as described in the cylinder head overhaul procedures.

Repair if necessary.

- Install the manifold and, working from the center outward, tighten the bolts

gradually and in several stages, to specifications.

- Install the following components in the reverse order of removal as required:

- Coolant bypass hose and bracket

- Upper radiator hose

- Front engine hanger and ground wire

- Secondary air pipe manifold

- Spark plugs

- Distributor (see the beginning of this section for installation procedures)

- Connect the following components:

- Spark plug wires

- Engine harness connectors

- Canister hoses

- Vacuum hoses (including brake)

- Heater hoses

- Fuel pump and fuel hoses

- Accelerator and cruise control cables

- PCV valve hose

- Install the oil dipstick and refill the cooling system. Adjust all the linkages

and cables. Set the ignition timing and the idle speed, as described in Section

2.

CAUTION

Before removing the intake manifold, release the fuel system pressure. (See

Section 5 for details.)

- Disconnect the negative battery cable and drain the cooling system.

- Disconnect the accelerator cable from the throttle body. Label and disconnect

all air and vacuum hoses from the dynamic chamber and the throttle body.

- Loosen the hose clamps, then disconnect the air funnel from the air flow

meter and the throttle body. On turbocharged engines, disconnect the air funnel

from the throttle body and the intercooler.

- Disconnect the spark plug wires from the distributor and unplug the connector

from the ignition coil. Loosen the hose clamp on the flexible hose and disconnect

the hose from the air cleaner assembly. Unfasten the bolts from the air cleaner

cover and remove the air cleaner/air flow meter assembly from the vehicle.

- Disconnect the water hoses and the throttle sensor connector. Remove the

retaining nuts and bolts from the throttle body, then separate the throttle

body from the intake manifold.

- Disconnect the hoses and remove the BAC valve. On turbocharged engines,

disconnect the water hose for the oil cooler and plug the opening to prevent

leakage.

- On turbocharged engines, unbolt the intake manifold and dynamic chamber

assembly from the cylinder block, then lift it out of the vehicle.

- On non turbocharged engines, unbolt the dynamic chamber from the intake

manifold and remove it along with the gasket, then remove the intake manifold.

- Remove the intake manifold gasket from the cylinder block. Cover or plug

the intake ports to prevent anything from falling into the engine.

- Thoroughly clean the intake manifold and cylinder block gasket mating surfaces.

Visually inspect the intake manifold and dynamic chamber for cracks.

To install:

- Place a new gasket on the cylinder block and lower the intake manifold onto

the gasket. On turbocharged engines, attach the dynamic chamber to the intake

manifold with a new gasket. Install the retaining nuts and bolts and torque

them to 14–19 ft. lbs. (19–26 Nm).

- Install the remaining components in the reverse order of removal:

- Oil cooler water hose (turbocharged engines)

- BAC valve and hoses

- Throttle body (with new gasket) and throttle sensor connector

- Water and vacuum hoses

- Air cleaner/air flow meter assembly, spark plug wires and distributor

connector

- Air funnel

- Accelerator cable

- Refill the cooling system to the proper level and connect the negative battery

cable. Check the accelerator cable deflection.

CAUTION

Before removing the intake manifold, release the fuel system pressure. (See

Section 5 for details.)

- Disconnect the negative battery cable and drain the cooling system.

- Unplug the air flow meter connector. Disconnect the air cleaner duct (1987

only), secondary air hoses and air control vacuum hoses, then remove the air

cleaner. On 1988–89 models, disconnect and remove the air duct along

with the No. 1 resonance chamber.

- Remove the air flow meter and attendant air hoses. On 1988–89 non-turbocharged

engines, the No. 2 resonance chamber is connected to the bottom of the flexible

air hose by a small hose with a hose clamp, and is retained by one attaching

screw. Disconnect and remove the No. 2 resonance chamber.

- On 1988–89 turbocharged engines, trace the upper hose on the intercooler

to the air bypass valve. (There are three hoses connected to the valve.) Loosen

the hose clamps and disconnect the hoses. Unbolt and remove the air bypass

valve from its mounting bracket, then remove the intercooler.

- Unfasten the electrical connectors from the throttle body. Disconnect the

water and vacuum hoses, then plug the openings.

- Disconnect the accelerator cable from the throttle body and remove the throttle

body (with gasket) from the dynamic chamber.

- Disconnect the PCV hose and the vacuum pipe assembly. Remove the nuts and

bolts that attach the dynamic chamber to the intake manifold and remove it

along with the gasket.

- Unfasten connectors from the fuel injectors, then route the wiring harness

off to the side and out of the way. Disconnect the fuel hose from the injector

rail and remove the rail assembly with the injectors attached. Plug all the

fuel openings.

- Disconnect the remaining vacuum hoses and remove the EGR pipe.

- Remove the intake manifold bracket, followed by the intake manifold and

gasket. Cover or plug the intake ports with clean rags or masking tape to

prevent anything from falling into the engine.

- Thoroughly clean the intake manifold and cylinder block gasket mating surfaces

with a gasket scraper and solvent. Visually inspect the intake manifold and

dynamic chamber for cracks.

To install:

- Place a new gasket on the cylinder block and lower the intake manifold onto

the gasket. Install the retaining nuts and torque them to 14–22 ft.

lbs. (19–30 Nm).

- Install the remaining components in the reverse order of removal:

- Intake manifold bracket

- EGR pipe and vacuum hoses

- Fuel rail and injector harness assembly

- Dynamic chamber with new gasket

- Vacuum pipe assembly and PCV hose

- Throttle body with new gasket

- Accelerator cable

- Vacuum and water hoses

- Throttle body connectors

- Intercooler

- Air bypass valve with hoses

- No. 2 resonance chamber (1988–89 non-turbocharged models only)

- Airflow meter

- No. 1 resonance chamber

- Air duct, air cleaner and air flow meter connector

- Refill the cooling system to the proper level and connect the negative battery

cable. Check the accelerator cable deflection.

CAUTION

Before removing the intake manifold, release the fuel system pressure. Please

refer to Section 5 for details on releasing the fuel system pressure.

- Disconnect the negative battery cable. Disconnect the coolant hoses and

plug them. (The coolant will be drained from the radiator just before the

intake manifold is ready to be removed.)

- Disconnect the air inlet duct from the air cleaner and unplug the air flow

meter connector.

- Locate the two solenoid valves (TICS and purge air control) that are bolted

to the front of the air cleaner. Label and disconnect the vacuum hoses.

- Remove the air cleaner assembly, air flow meter and air funnel.

- Disconnect the Bypass Air Control (BAC) valve connector and coolant hoses,

then remove the valve.

- Disconnect the throttle sensor connector and the accelerator cable. Remove

the throttle body and gasket.

- Disconnect all vacuum hoses, EGR pipe, EGR position sensor connector, coolant

hose and ground wire.

| Fig. 3: Intake manifold loosening sequence — 929

|

| Fig. 4: Intake manifold tightening sequence — 929

|

- Remove the wiring harness bracket.

- Disconnect the air intake pipe from the dynamic chamber with the gasket.

- Mark the extension manifolds RIGHT and LEFT for assembly reference, as they

are not interchangeable. Remove the six extension manifolds with their gaskets

from the dynamic chamber.

- Disconnect the intake air thermosensor connector, vacuum hoses and ground

connectors.

- Remove the attaching nuts and lift the dynamic chamber straight up from

the intake manifold studs. Drain the radiator at this time and disconnect

all remaining connectors, fuel hoses, and coolant hoses.

- Using the sequence shown in the illustration, loosen the intake manifold

nuts in two stages. Lift the intake manifold from the engine and remove the

two intake manifold gaskets. Insert clean rags into the intake ports or cover

them with masking tape to prevent anything from falling into the engine.

- Immerse the intake manifold in a suitable solvent and blow it dry with compressed

air. Visually inspect the intake manifold for cracks, warpage or any other

type of damage and replace as necessary. Remove all gasket material from the

seating surface on the manifold and the engine. Forward of one of the studs

that secures the dynamic chamber is an O-ring that seals the manifold to the

dynamic chamber. Remove this O-ring and replace it with a new one.

To install:

- Place the new intake manifold gaskets onto the cylinder block and lower

the manifold over the gaskets. Install the intake manifold washers with the

white paint marks facing up. Install the retaining nuts and torque them in

two stages to 14–18 ft. lbs. (19–24 Nm) using the sequence shown

in the illustration.

- Install the remaining components in the reverse of the removal procedure:

- Connectors, fuel hoses, coolant hoses and vacuum hoses.

- Dynamic chamber. Torque the retaining nuts to 14–18 ft. lbs. (19–24

Nm)..

- Intake air thermosensor ground connectors and vacuum hoses.

- Extension manifolds with new gaskets and O-rings.

- Intake air pipe with new gaskets and wiring bracket.

- Ground wire, coolant hose, EGR position connector, EGR pipe and vacuum

hoses.

- Throttle body with new gasket, accelerator cable and throttle sensor

connector. Check the deflection of the accelerator cable. If not within

0.04–0.12 in. (1–3mm), adjust with the nuts on the cable bracket.

- BAC valve, coolant hoses and connector.

- Air funnel, air hoses, air flow meter, and air cleaner assembly.

- TICS and purge control solenoid valves, air flow meter connector, vacuum

chamber and air duct.

- Make sure that all hose connections are tight, then refill the cooling system

to the proper level. Connect the negative battery cable. Start the engine

and check for leaks.