CAUTION

The clutch driven disc may contain asbestos, which has been determined to be

a cancer causing agent. Never clean clutch surfaces with compressed air! Avoid

inhaling any dust from any clutch surface! When cleaning clutch surfaces, use

a commercially available brake cleaning fluid.

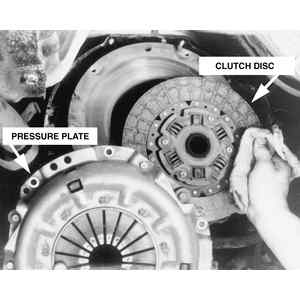

| Fig. 1: Exploded view of the clutch and pressure plate

assembly

|

| Fig. 2: Loosen and remove the clutch and pressure plate

bolts evenly, a little at a time . . .

|

| Fig. 3: . . . then carefully remove the pressure plate

and clutch assembly from the flywheel

|

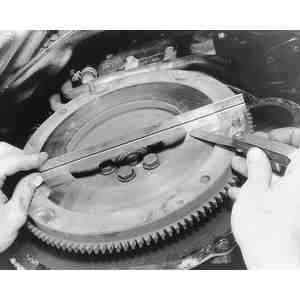

| Fig. 4: Check the flywheel surface for flatness and,

if necessary, remove it from the engine for truing

|

- Remove the transmission.

- Remove the four attaching and two pilot bolts holding the clutch cover to

the flywheel. Loosen the bolts evenly and a turn or two at a time. If the

clutch cover is to be reinstalled, mark the flywheel and clutch cover to show

the location of the two pilot holes.

- Remove the clutch disc.

- Install the clutch disc on the flywheel. Do not touch the facing or allow

the facing to come in contact with grease or oil. The clutch disc can be aligned

using a tool made for that purpose, or with an old mainshaft.

- Install the clutch cover on the flywheel and install the four standard bolts

and the two pilot bolts.

- To avoid distorting the pressure plate, tighten the bolts evenly a few turns

at a time until they are all tight.

| Fig. 5: Be sure that the flywheel surface is clean

before installing the clutch

|

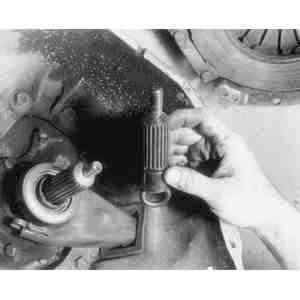

| Fig. 6: Typical clutch alignment tool, note how the

splines match the transmission's input shaft

|

| Fig. 7: Use the clutch alignment tool to align the

clutch disc during assembly.

|

| Fig. 8: Be sure to use a torque wrench to tighten

all of the bolts

|

- Tighten the bolts to 13–20 ft.lbs. (18–27 Nm). using a crossing

pattern.

- Remove the aligning tool.

- Apply a light film of lubricant to the release bearing, release lever contact

area on the release bearing hub and to the input shaft bearing retainer.

- Install the transmission.

- Check the operation of the clutch and if necessary, adjust the pedal free-play

and the release lever.

| Fig. 9: Exploded view of the clutch components

|

- Disconnect the negative battery cable.

- Disconnect the clutch hydraulic system master cylinder from the clutch pedal

and remove.

- Raise the vehicle and support it safely.

- Remove the starter.

- Disconnect the hydraulic coupling at the transmission.

NOTE: Clean the area around the hose and slave cylinder

to prevent fluid contamination.

- Remove the transmission from the vehicle.

- Mark the assembled position of the pressure plate and cover the flywheel,

to aid during re-assembly.

- Loosen the pressure plate and cover attaching bolts evenly until the pressure

plate springs are expanded, and remove the bolts.

- Remove the pressure plate and cover assembly and the clutch disc from the

flywheel. Remove the pilot bearing only for replacement.

To install:

- Position the clutch disc on the flywheel so that the Clutch Alignment Shaft

Tool T74P–7137–K or equivalent can enter the clutch pilot bearing

and align the disc.

| Fig. 10: Pressure plate bolt torque sequence

|

- When reinstalling the original pressure plate and cover assembly, align

the assembly and flywheel according to the marks made during the removal operations.

Position the pressure plate and cover assembly on the flywheel, align the

pressure plate and disc, and install the retaining bolts that fasten the assembly

to the flywheel. Tighten the bolts to 15–25 ft.lbs. (21–35 Nm)

in the proper sequence. Remove the clutch disc pilot tool.

- Install the transmission into the vehicle.

- Connect the coupling by pushing the male coupling into the slave cylinder.

- Connect the hydraulic clutch master cylinder pushrod to the clutch pedal.