The first step for any assembly job is to have a clean area in which

to work. Next, thoroughly clean all of the parts and components that

are to be assembled. Finally, place all of the components onto a suitable

work space and, if necessary, arrange the parts to their respective

positions.

- Lightly lubricate the valve stems and insert all of the valves into

the cylinder head. If possible, maintain their original locations.

- If equipped, install any valve spring shims which were removed.

- If equipped, install the new valve seals, keeping the following

in mind:

- If the valve seal presses over the guide, lightly lubricate

the outer guide surfaces.

- If the seal is an O-ring type, it is installed just after compressing

the spring but before the valve locks.

- Place the valve spring and retainer over the stem.

- Position the spring compressor tool and compress the spring.

- Assemble the valve locks to the stem.

- Relieve the spring pressure slowly and insure that neither valve

lock becomes dislodged by the retainer.

- Remove the spring compressor tool.

- Repeat Steps 2 through 8 until all of the springs have been installed.

To install the springs, retainers and valve locks on heads which have

these components recessed into the camshaft follower's bore, you will

need a small screwdriver-type tool, some clean white grease and a lot

of patience. You will also need the C-clamp style spring compressor

and the OHC tool used to disassemble the head.

- Lightly lubricate the valve stems and insert all of the valves into

the cylinder head. If possible, maintain their original locations.

- If equipped, install any valve spring shims which were removed.

- If equipped, install the new valve seals, keeping the following

in mind:

- If the valve seal presses over the guide, lightly lubricate

the outer guide surfaces.

- If the seal is an O-ring type, it is installed just after compressing

the spring but before the valve locks.

- Place the valve spring and retainer over the stem.

- Position the spring compressor and the OHC tool, then compress the

spring.

- Using a small screwdriver as a spatula, fill the valve stem side

of the lock with white grease. Use the excess grease on the screwdriver

to fasten the lock to the driver.

- Carefully install the valve lock, which is stuck to the end of the

screwdriver, to the valve stem then press on it with the screwdriver

until the grease squeezes out. The valve lock should now be stuck

to the stem.

- Repeat Steps 6 and 7 for the remaining valve lock.

- Relieve the spring pressure slowly and insure that neither valve

lock becomes dislodged by the retainer.

- Remove the spring compressor tool.

- Repeat Steps 2 through 10 until all of the springs have been installed.

- Install the followers, camshaft(s) and any other components that

were removed for disassembly.

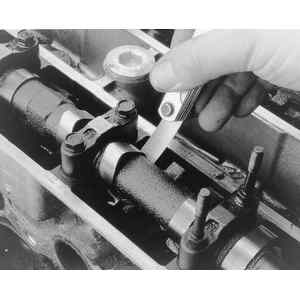

| Fig. 1: Once assembled, check the valve clearance

and correct as needed

|

- Lightly lubricate the valve stems and insert all of the valves into

the cylinder head. If possible, maintain their original locations.

- If equipped, install any valve spring shims which were removed.

- If equipped, install the new valve seals, keeping the following

in mind:

- If the valve seal presses over the guide, lightly lubricate

the outer guide surfaces.

- If the seal is an O-ring type, it is installed just after compressing

the spring but before the valve locks.

- Place the valve spring and retainer over the stem.

- Position the spring compressor tool and compress the spring.

- Assemble the valve locks to the stem.

- Relieve the spring pressure slowly and insure that neither valve

lock becomes dislodged by the retainer.

- Remove the spring compressor tool.

- Repeat Steps 2 through 8 until all of the springs have been installed.

- Install the camshaft(s), rockers, shafts and any other components

that were removed for disassembly.