CAUTION

Fuel injection systems remain under pressure after the engine has been turned

OFF. Properly relieve fuel pressure before disconnecting any fuel lines. Failure

to do so may result in fire or personal injury. Do not allow fuel spray or fuel

vapors to come in contact with a spark or open flame. Keep a dry chemical fire

extinguisher nearby. Never store fuel in an open container due to risk of fire

or explosion.

- Relieve the fuel system pressure, and disconnect the negative battery cable.

- Remove the timing chain cover bolts and the cover.

- Remove the spacer, the idler sprocket assembly lock bolt, the chain guides,

and the idler sprocket assembly.

- Remove the balancer chain.

- Remove the timing chain adjuster and the timing chain.

- Remove the lock bolts and remove the crankshaft timing sprocket and the

camshaft sprocket.

- Remove the key and the chain lever and guide.

- Inspect the chain, sprockets and guides for damage and/or wear.

To install:

- Install the timing chain guides and tighten to 7–9 ft. lbs. (10–12

Nm).

- If removed, install the tensioner onto the cylinder block.

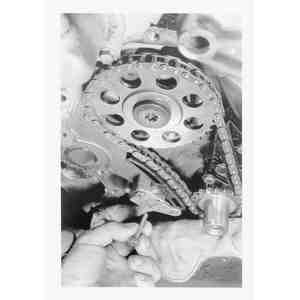

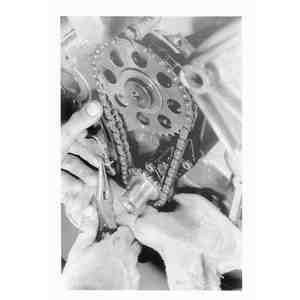

- Align the plated links of the timing chain with the timing marks on the

sprockets as the chain and sprockets are assembled. Secure the pulley and

chain with wire to prevent misalignment.

| Fig. 1: Crankshaft sprocket chain alignment — 2.6L

engine

|

| Fig. 2: Camshaft sprocket chain alignment — 2.6L

engine

|

- Hold the chain tensioner head in, then slide the crankshaft sprocket onto

the crankshaft and place the camshaft sprocket on the sprocket holder.

- Install the balancer shaft drive sprocket on the crankshaft. Assemble the

balancer shaft sprockets to the balancer shaft chain, making sure the timing

marks on the sprockets are aligned with the polished links on the chain.

NOTE: Be careful not to confuse the right and left sprockets

as they are installed in opposite directions.

- While holding the assembled sprockets and chain, align the timing mark on

the crankshaft sprocket with the chain and install the balancer shaft sprockets.

Temporarily tighten the bolts by hand.

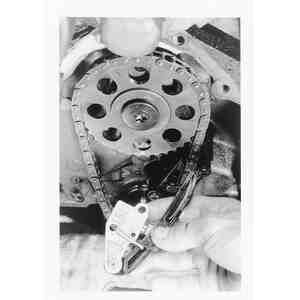

| Fig. 3: Balancer chain and sprocket alignment — 2.6L

engine

|

- Install the right and left lower balancer chain guides and tighten the mounting

bolts to 69–95 inch lbs. (7.8–11.0 Nm).

- Install the upper chain guide and loosely tighten the mounting and adjusting

bolts. Set the chain guide to the fully downward position.

- Tighten the idler sprocket assembly lock bolt to 27–38 ft. lbs. (37–52

Nm), and install the spacer.

- Rotate both balancer shaft sprockets slightly to position the chain slack

at the center between the left balancer shaft sprocket and the oil pump sprocket.

- Adjust the balancer chain tension as follows:

- Loosen the upper chain guide adjusting bolt.

- Push on the chain guide just above the adjusting slot with a force of

approximately 11 lbs. (49N), then pull back the guide 0.126–0.149

inch (3.2–3.8mm). Tighten the bolt to 69–95 inch lbs. (7.8–11.0

Nm). Tighten the guide pivot bolt to the same specification.

- The chain slack at the notch in the guide should be 0.12 inch (3mm)

when the guide is properly adjusted.

- Install the timing chain cover with a new gasket.

- Fill the crankcase with the proper type and quantity of engine oil. Fill

and bleed the cooling system. Run the engine and check for leaks and proper

operation.

- Check the idle speed and ignition timing and adjust, if necessary.

- Disconnect the negative battery cable.

- Drain the cooling system and crankcase.

CAUTION

When draining the coolant, keep in mind that cats and dogs are attracted

by ethylene glycol antifreeze, and are quite likely to drink any that is

left in an uncovered container or in puddles on the ground. This will prove

fatal in sufficient quantity. Always drain the coolant into a sealable container.

Coolant should be reused unless it is contaminated or several years old.

- Remove the timing chain cover.

| Fig. 4: Timing mark alignment — 3.0L

engine

|

| Fig. 5: Timing chain mounting — 3.0L

engine

|

- Rotate crankshaft until No. 1 piston is at TDC and timing marks are aligned

in the correct position.

- Remove the camshaft sprocket retaining bolt and washer. Check timing chain

deflection for excessive wear.

- Slide sprockets and timing chain forward and remove as assembly.

To install:

- Clean timing cover and oil pan sealing surfaces. Clean and inspect all parts.

The camshaft retaining bolt has a drilled oil passage for timing chain assembly

lubrication. Clean oil passage with solvent. Do not replace with standard

bolt.

- Slide sprockets and timing chain on as assembly with timing marks in the

correct location. Install camshaft retaining bolt and washer. Tighten bolt

to 46 ft. lbs. (62 Nm). Lubricate the timing chain assembly.

- Install timing cover assembly. Install retaining bolts with pipe sealant

and tighten as outlined.

- Refill and bleed cooling system. Connect the negative battery cable. Start

engine check for coolant, oil and exhaust leaks.

NOTE: Review the complete service procedure before starting

this repair. Refer to the necessary service procedures in this section.

- Disconnect the negative battery cable.

- Drain the cooling system.

CAUTION

When draining the coolant, keep in mind that cats and dogs are attracted

by ethylene glycol antifreeze, and are quite likely to drink any that is

left in an uncovered container or in puddles on the ground. This will prove

fatal in sufficient quantity. Always drain the coolant into a sealable container.

Coolant should be reused unless it is contaminated or several years old.

| Fig. 6: To remove the timing chain and sprockets,

first remove the engine front cover

|

- Remove the front cover.

- Remove the radiator.

| Fig. 7: Timing chain mounting — 4.0L

engine

|

- Rotate the engine by hand until the No.1 cylinder is at TDC compression,

and the timing marks are aligned.

| Fig. 8: Remove the tensioner lower attaching bolt

. . .

|

| Fig. 9: . . . and install a holding clip in the bolt

hole and the slot on the rubbing block

|

| Fig. 10: Unbolt and remove the tensioner

|

| Fig. 11: A close-up view of a homemade holding clip

. . .

|

| Fig. 12: . . . and its proper positioning on the

tensioner

|

- Remove the lower tensioner bolt and install a holding clip in the bolt hole

and the slot on the rubbing block. Unbolt and remove the tensioner.

- Remove the camshaft sprocket bolt and sprocket retaining key.

| Fig. 13: Loosen the camshaft sprocket bolt . . .

|

| Fig. 14: . . . then remove it

|

| Fig. 15: Remove the camshaft sprocket and chain

|

- Remove the camshaft and crankshaft sprockets with the timing chain.

| Fig. 16: If necessary, unbolt the chain guide attaching

bolts . . .

|

| Fig. 17: . . . and remove the guide from the engine

|

| Fig. 18: To remove the crankshaft sprocket, use a

chisel to loosen the keyway . . .

|

| Fig. 19: . . . then remove the keyway from the crankshaft

|

| Fig. 20: Using a jawed puller, tighten the center

bolt . . .

|

| Fig. 21: . . . and pull the crankshaft sprocket from

the engine

|

- If necessary, remove the chain guide.

To install:

- Install the timing chain guide. Make sure the pin of the guide is in the

hole in the block. Tighten the bolts to 84–96 inch lbs. (9–11

Nm).

- Align the timing marks on the crankshaft and camshaft sprockets and install

the sprockets and chain.

| Fig. 22: Timing chain alignment — 4.0L

engine

|

- Install the camshaft sprocket bolt and sprocket retaining key. Make sure

that the timing marks are still aligned.

- Install the tensioner with the clip in place to keep it retracted.

- Install the crankshaft key. Make sure the timing marks are still aligned.

- Make sure the tensioner side of the chain is held inward and the other side

is straight and tight.

- Install the camshaft sprocket bolt and tighten it to 50 ft. lbs. (68 Nm).

- Remove the tensioner clip.

- Check camshaft end-play.

- Install the front cover.

- Install the radiator.

- Fill the cooling system.

- Fill the crankcase to the proper level. Connect the negative battery cable.

Start engine check for leaks and roadtest the vehicle for proper operation.