Three types of connectors are commonly used in automotive applications-weatherproof,

molded and hard shell.

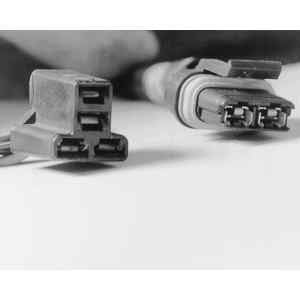

| Fig. 1: Hard shell (left) and weatherproof (right) connectors

have replaceable terminals

|

- Weatherproof[emdash]these connectors are most commonly used in the engine

compartment or where the connector is exposed to the elements. Terminals are

protected against moisture and dirt by sealing rings which provide a weathertight

seal. All repairs require the use of a special terminal and the tool required

to service it. Unlike standard blade type terminals, these weatherproof terminals

cannot be straightened once they are bent. Make certain that the connectors

are properly seated and all of the sealing rings are in place when connecting

leads.

- Molded[emdash]these connectors require complete replacement of the connector

if found to be defective. This means splicing a new connector assembly into

the harness. All splices should be soldered to insure proper contact. Use

care when probing the connections or replacing terminals in them, as it is

possible to create a short circuit between opposite terminals. If this happens

to the wrong terminal pair, it is possible to damage certain components. Always

use jumper wires between connectors for circuit checking and NEVER probe through

weatherproof seals.

- Hard Shell[emdash]unlike molded connectors, the terminal contacts in hard-shell

connectors can be replaced. Replacement usually involves the use of a special

terminal removal tool that depresses the locking tangs (barbs) on the connector

terminal and allows the connector to be removed from the rear of the shell.

The connector shell should be replaced if it shows any evidence of burning,

melting, cracks, or breaks. Replace individual terminals that are burnt, corroded,

distorted or loose.

| Fig. 2: Weatherproof connectors are most commonly

used in the engine compartment or where the connector is exposed to

the elements

|